Gallery details

PROJECT DETAILS

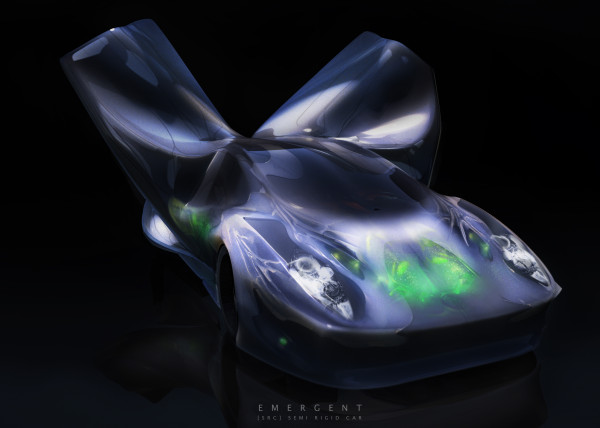

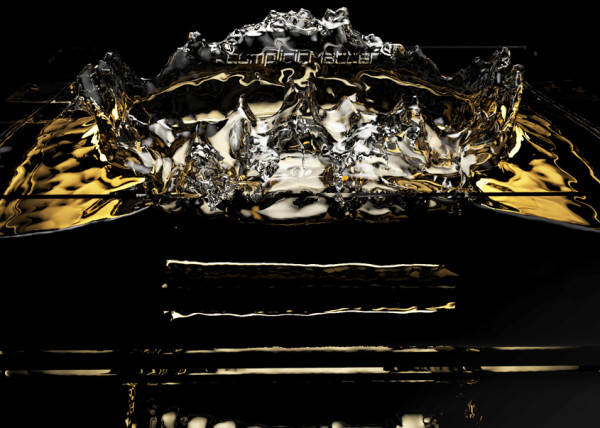

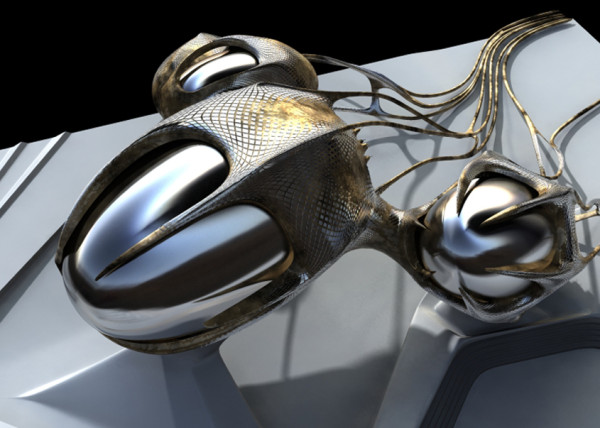

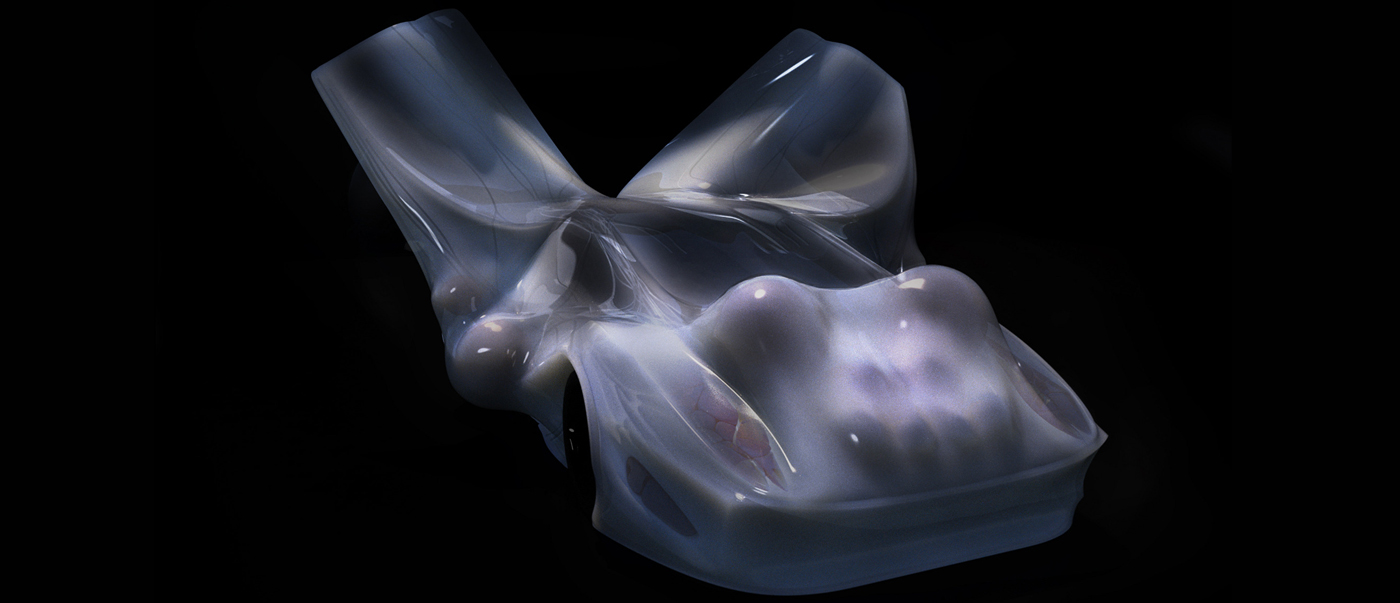

project : Semi Rigid Car [SRC]

client : Concept Competition for Renault

type : Multi-Material Car Prototype

material : synthetic cartilage, gel matrix, algae

location : Los Angeles, CA

Emergent Design Team:

Tom Wiscombe – Principal

David Stamatis – Senior Designer

Luis Quinones – Lead Designer

Project Team:

Josh Moratto

Robbie Eleazer

Ryan Lamb

Brent Lucy

Jason Orbe-Smith

Cindy Lin

PROJECT DESCRIPTION

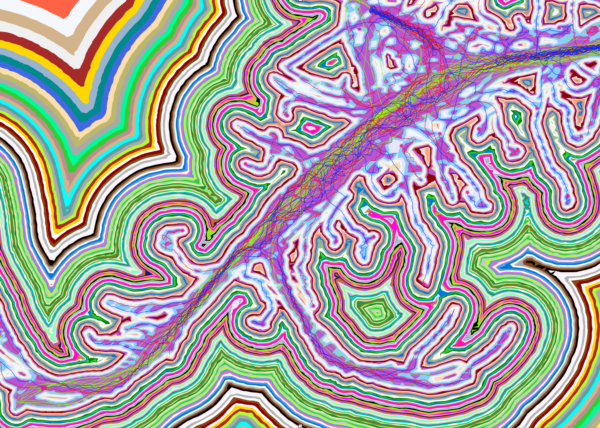

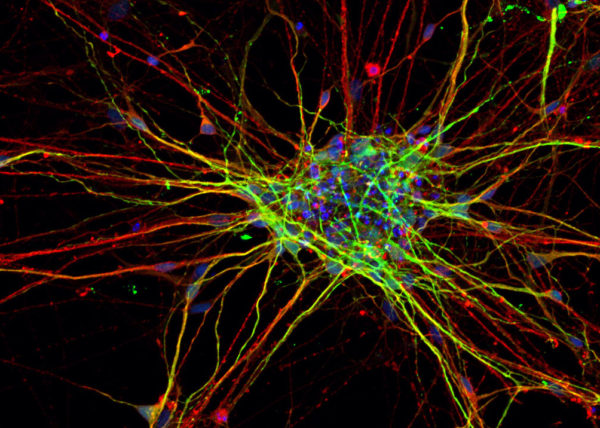

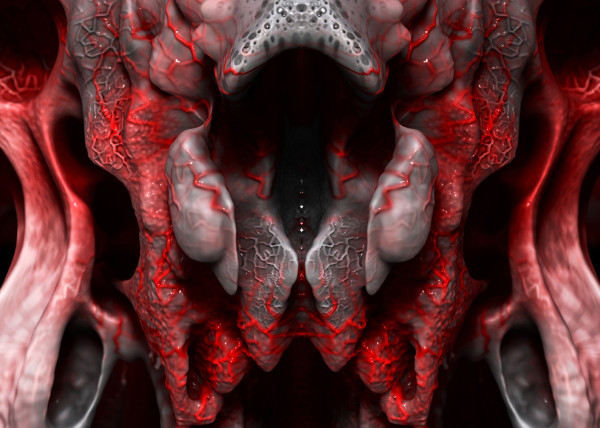

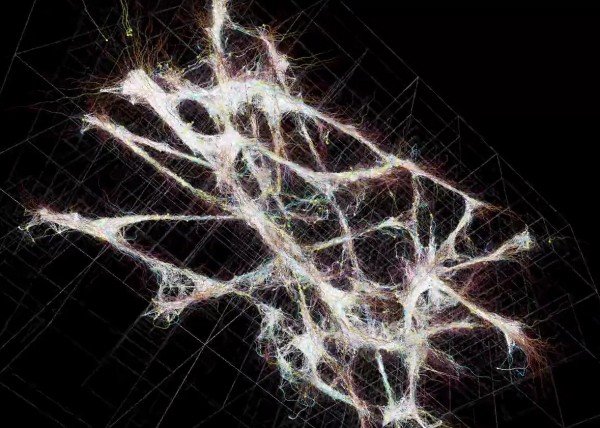

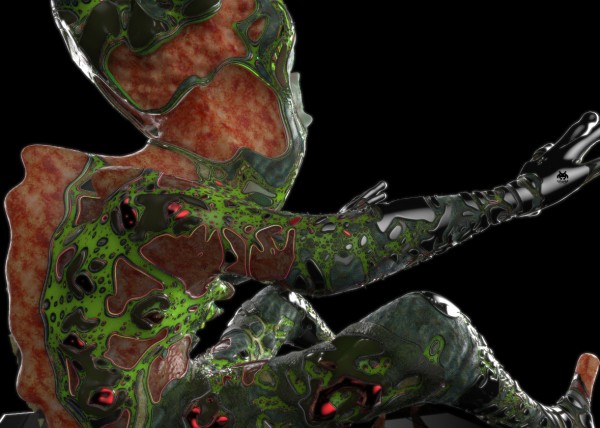

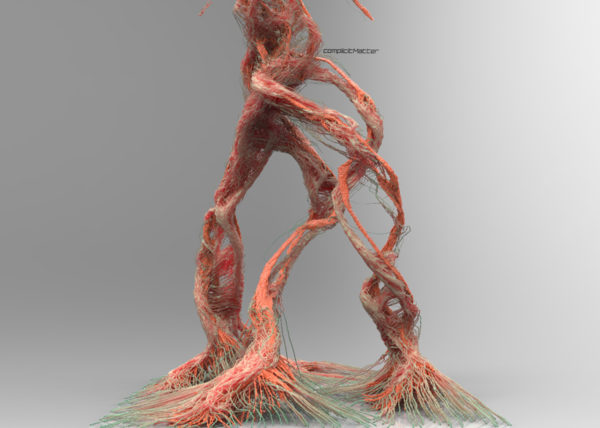

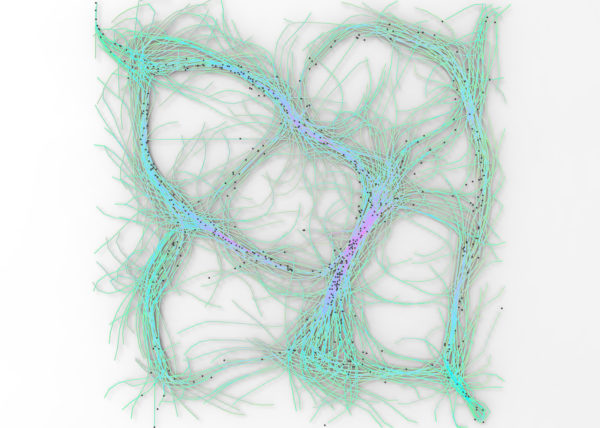

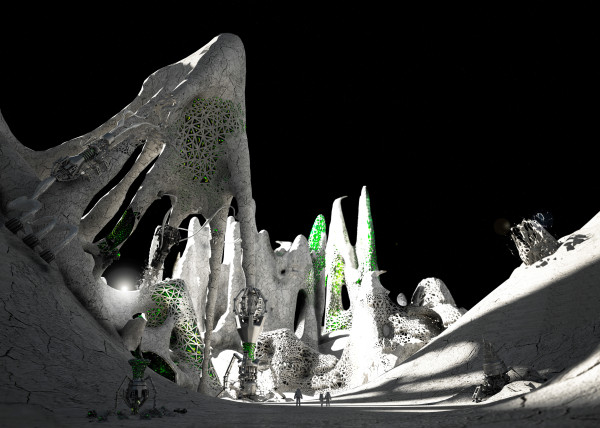

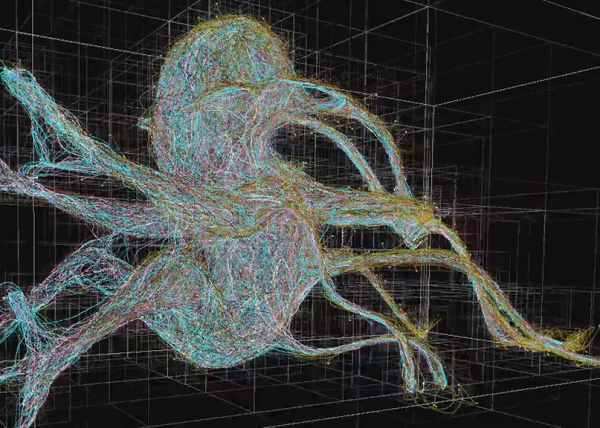

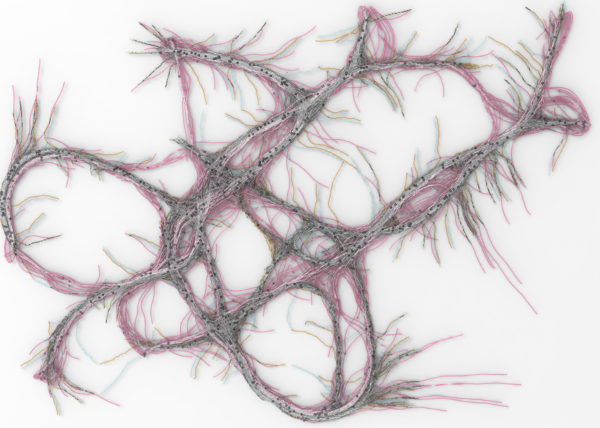

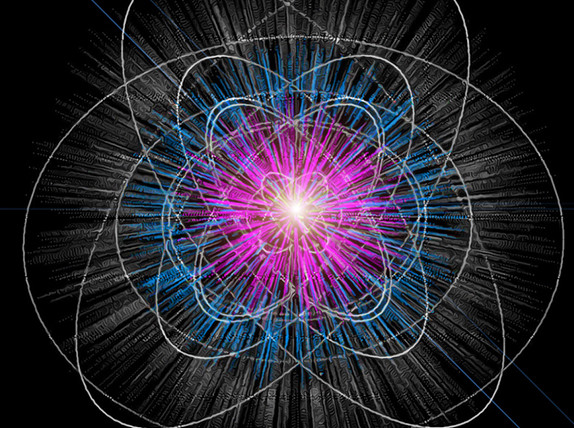

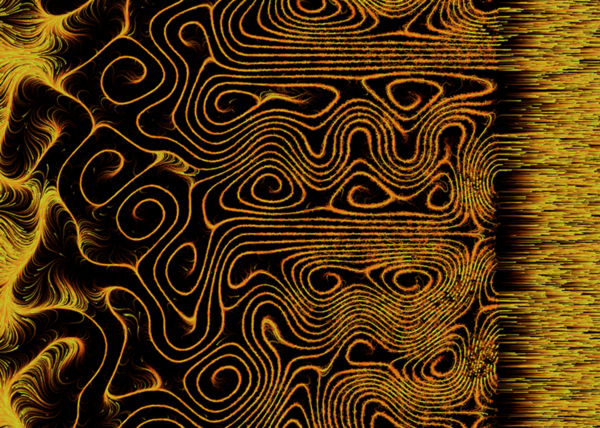

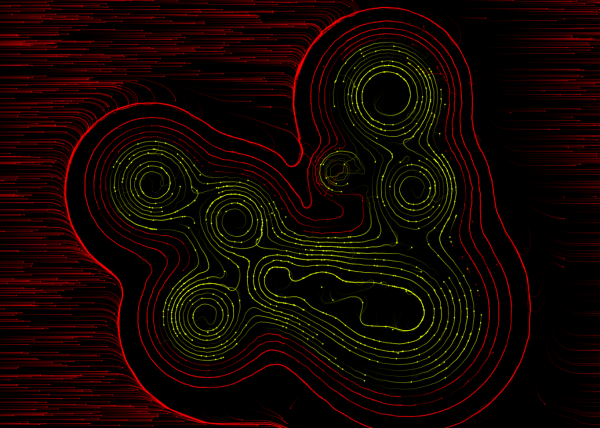

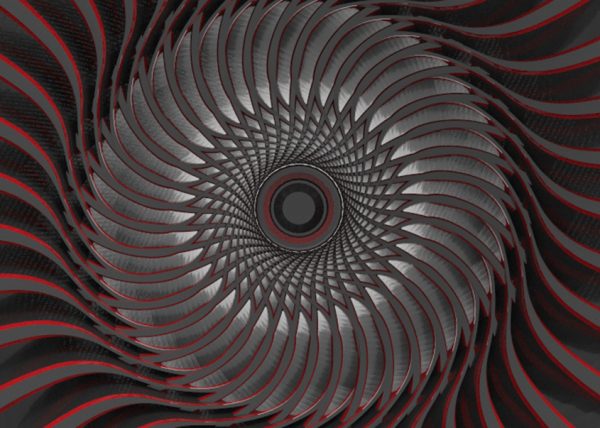

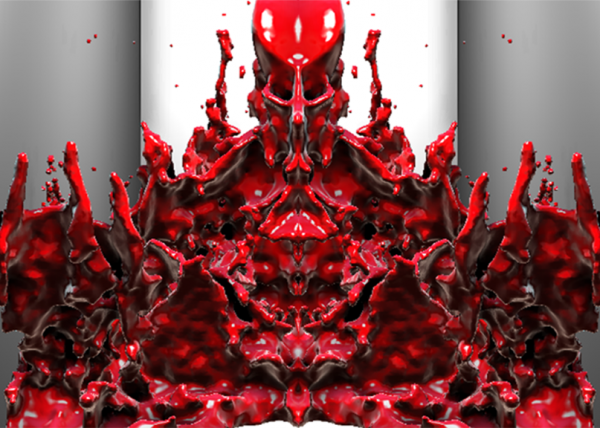

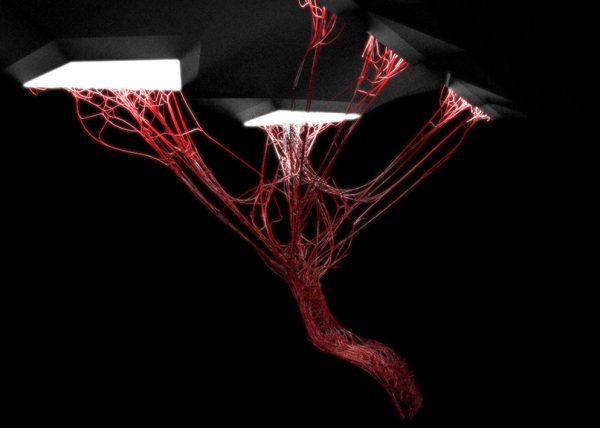

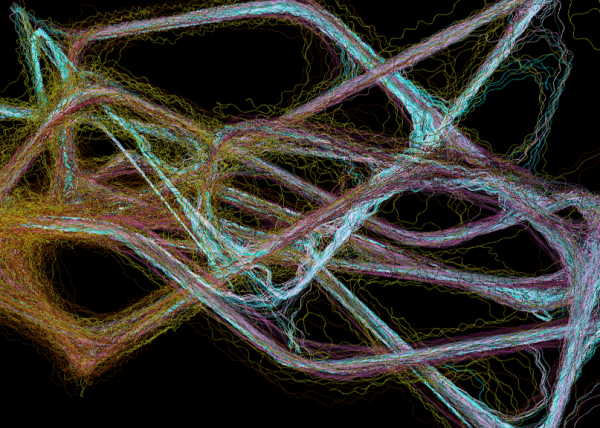

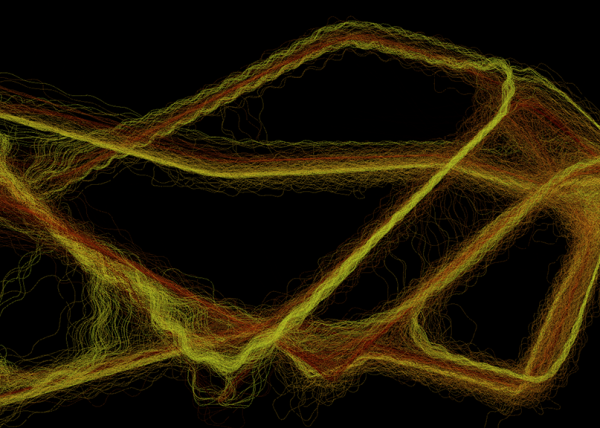

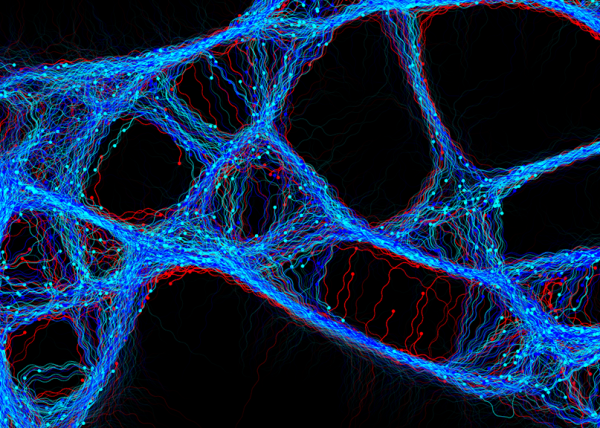

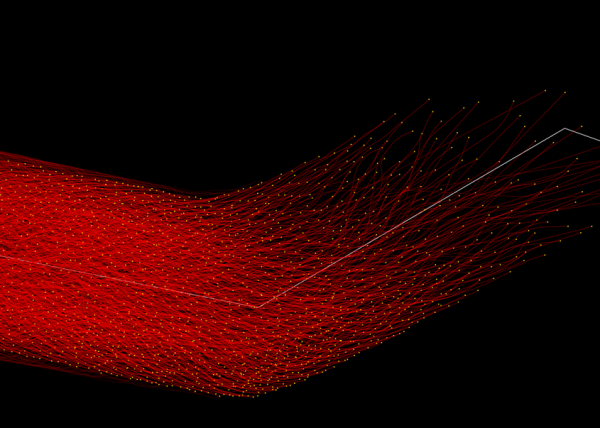

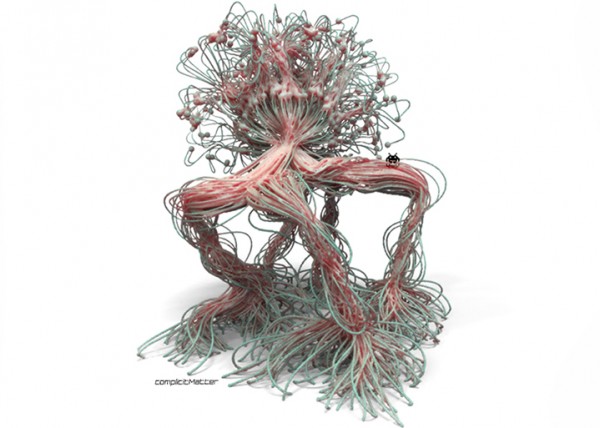

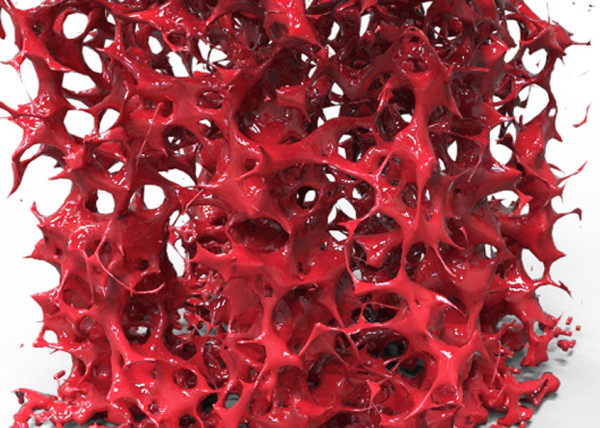

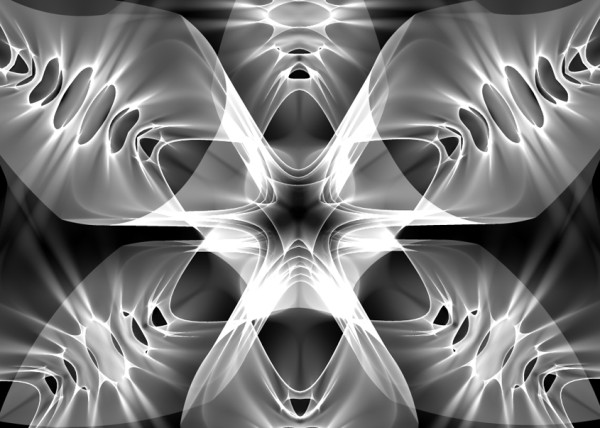

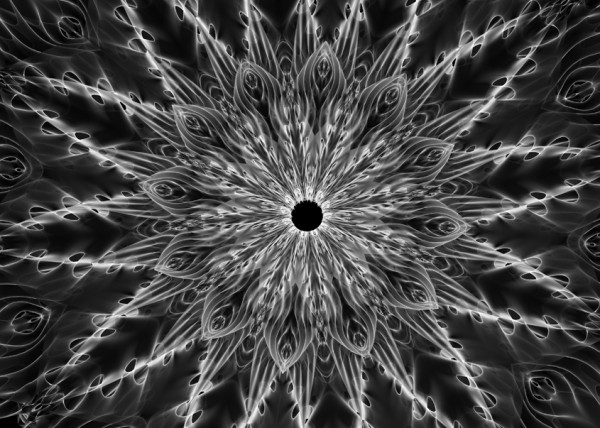

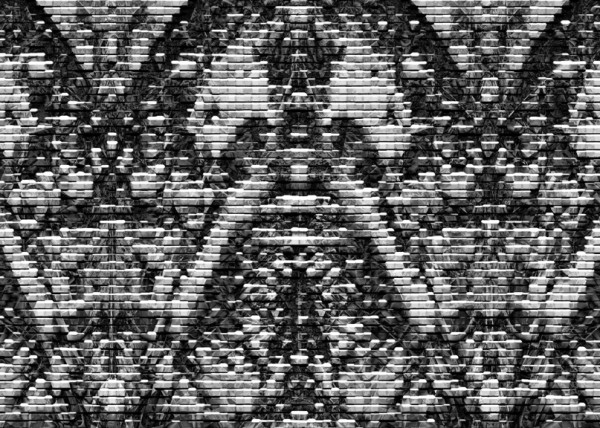

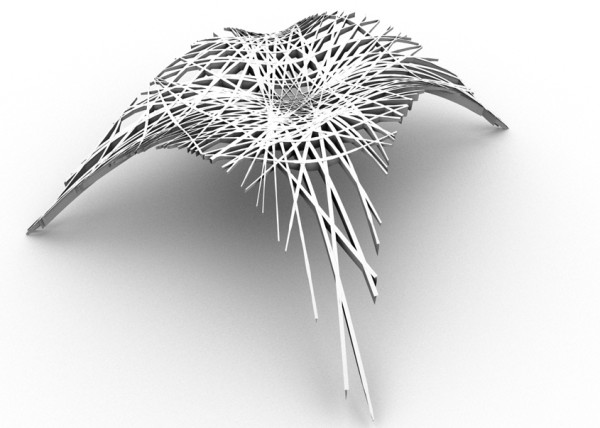

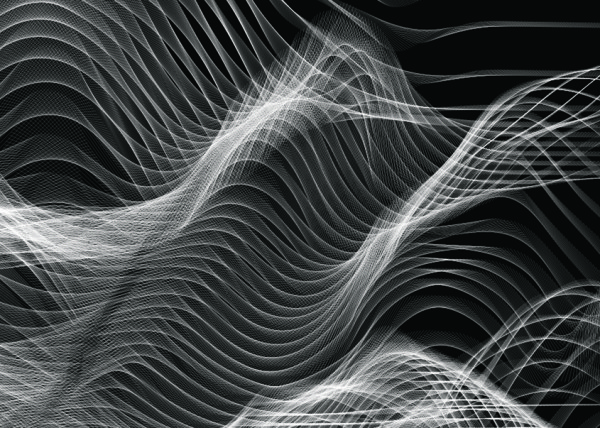

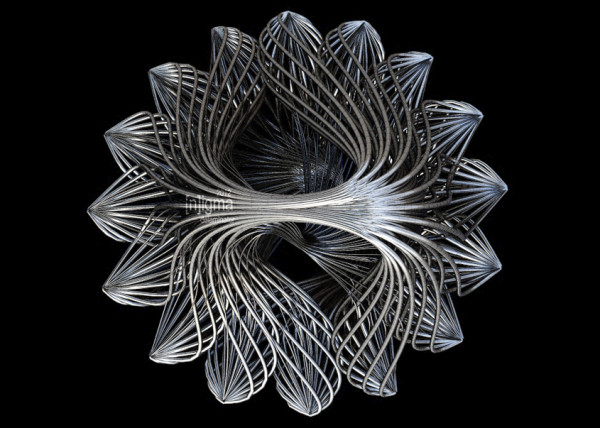

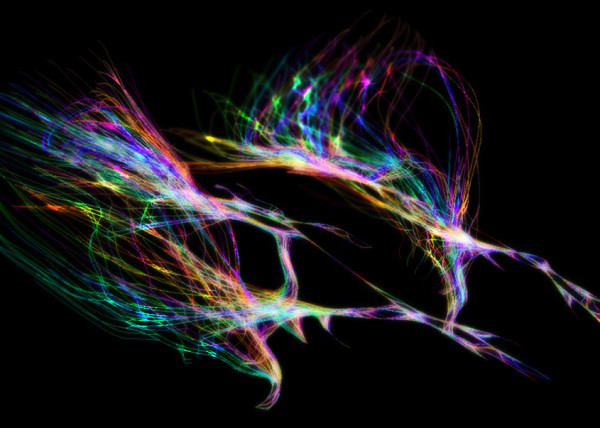

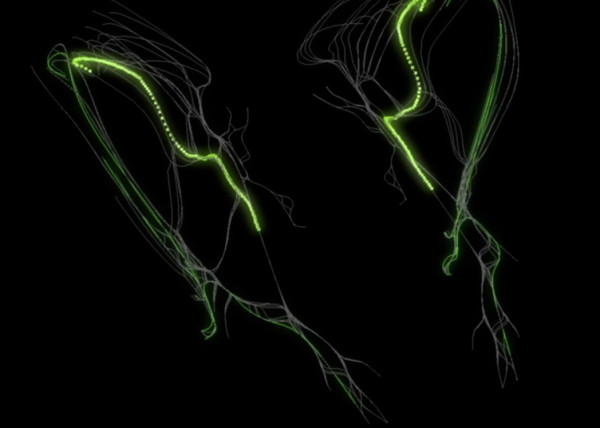

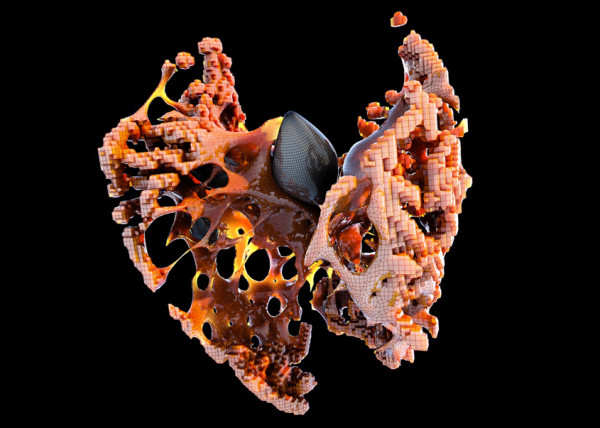

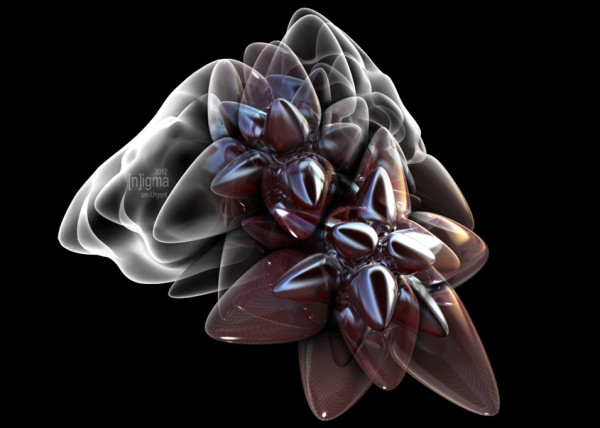

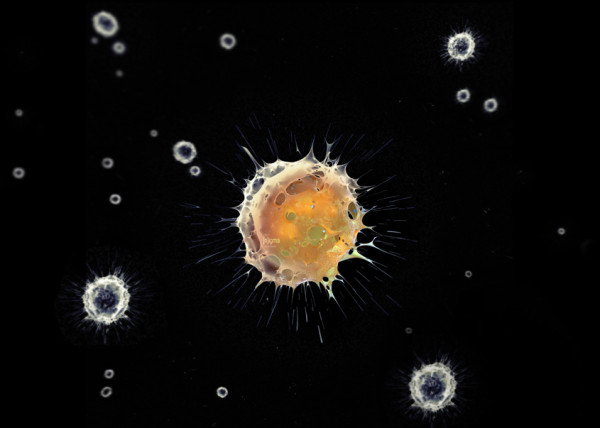

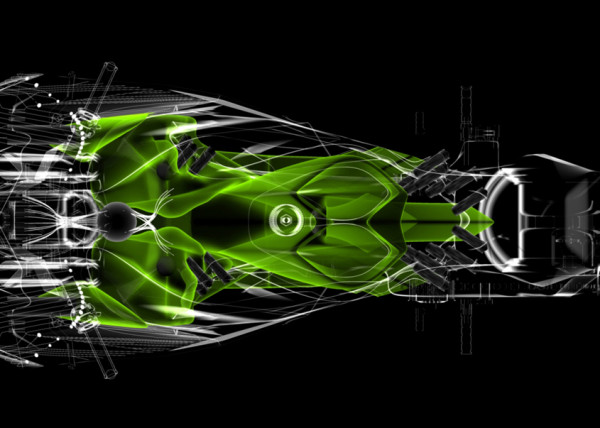

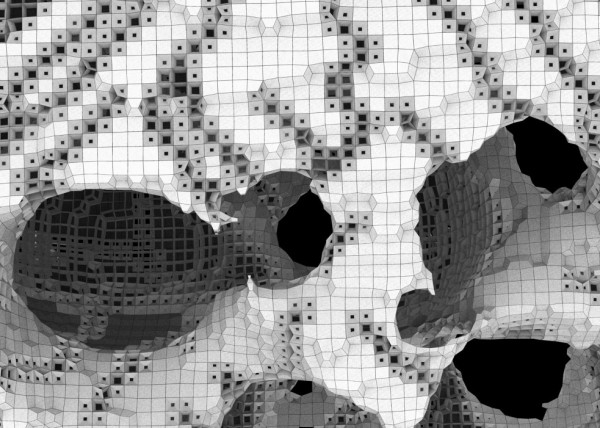

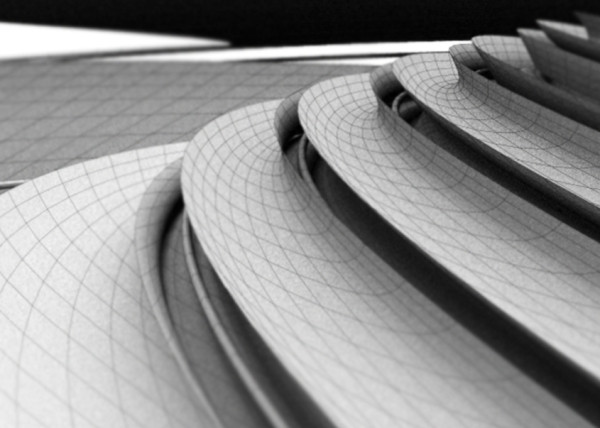

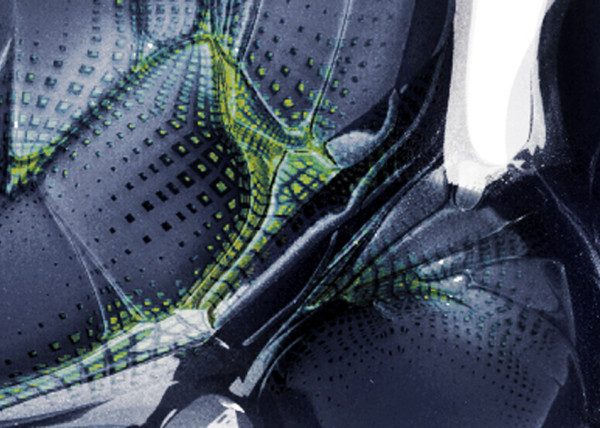

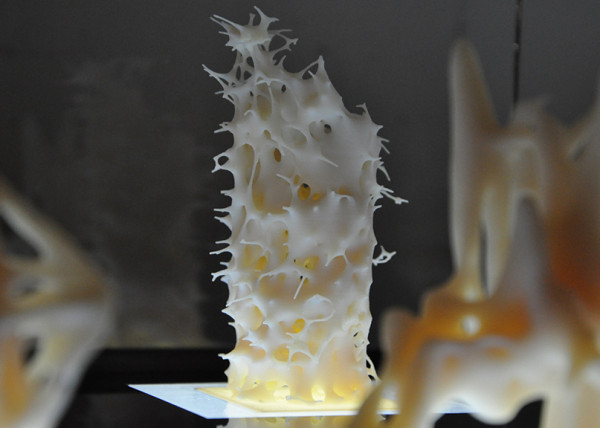

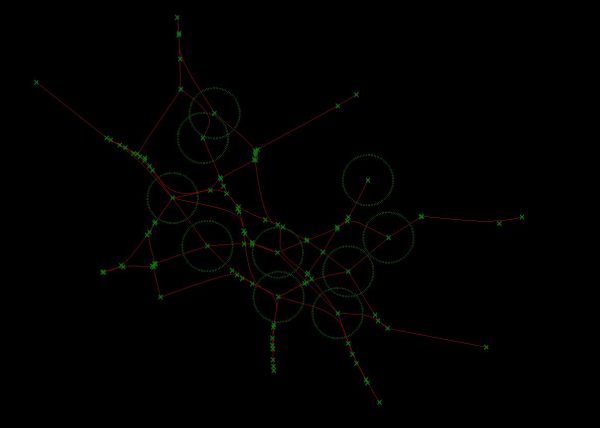

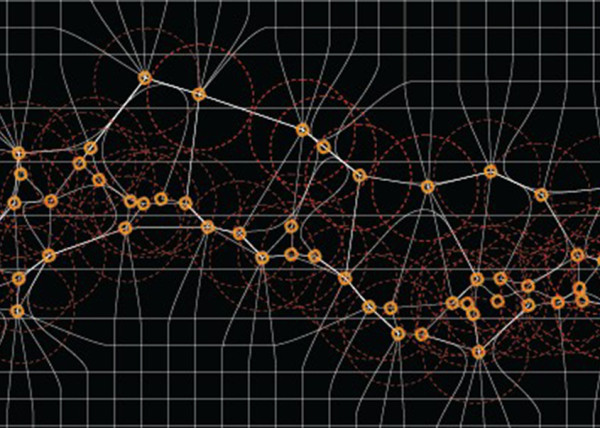

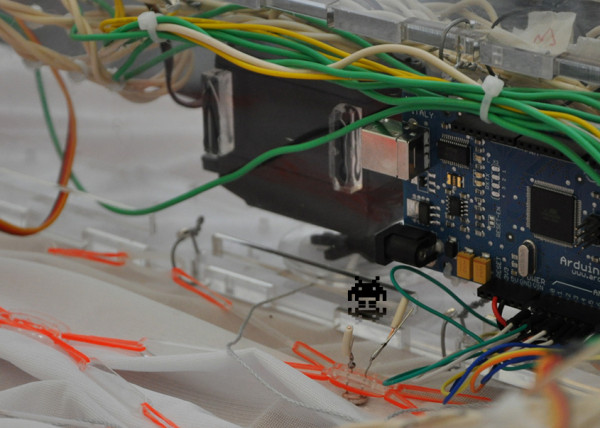

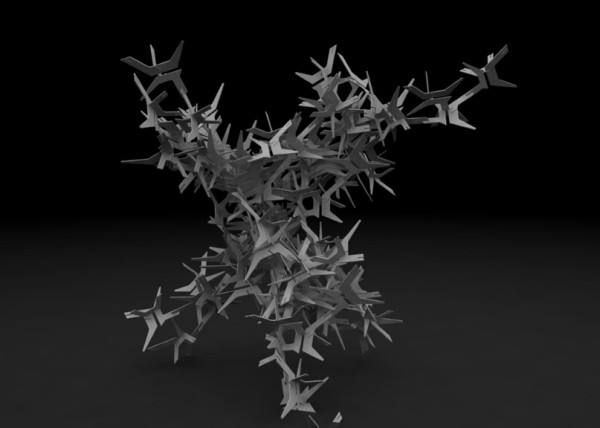

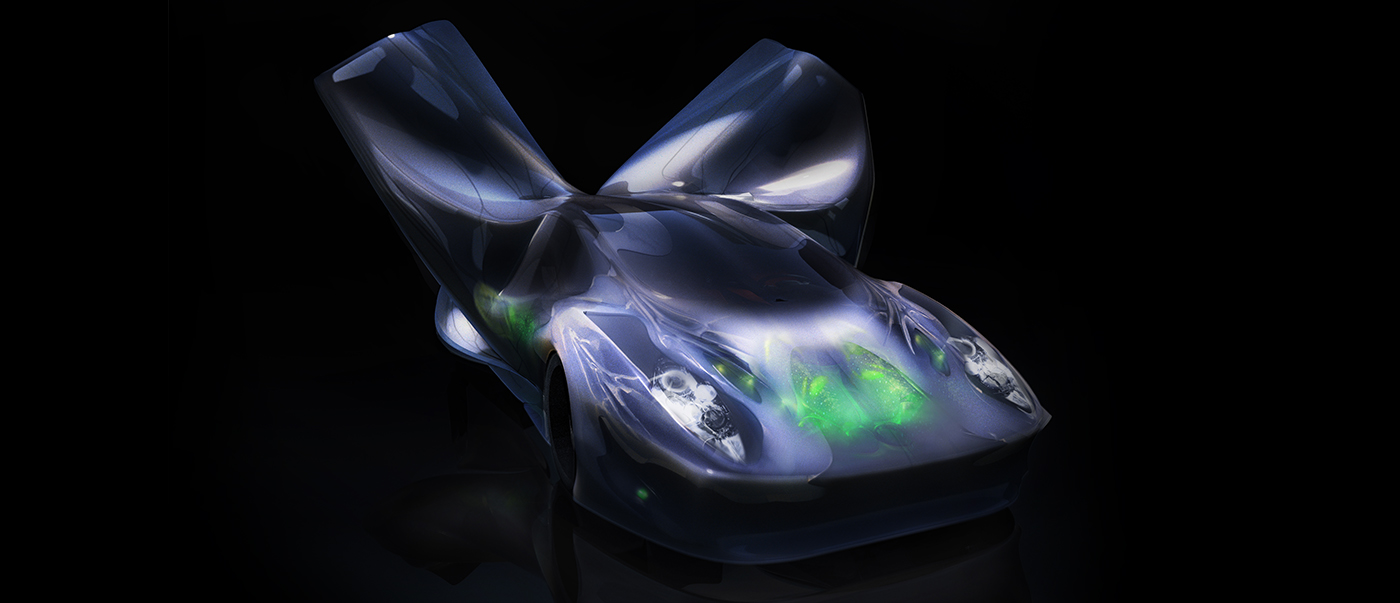

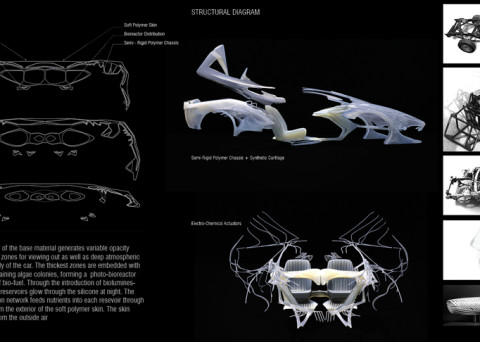

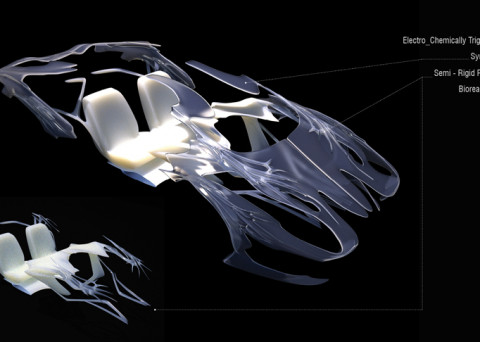

The Semi-Rigid Car is an experiment underwritten by the recent revolution in what we call multi-materiality in rapid prototyping. With the invention of 3D printers which not only print in multiple materials simultaneously, but in gradient mixtures of these materials, fabrication as we have understood it is transformed. No longer based on tectonics or assembly of parts, fabrication has suddenly become a new form of alchemy. Variable opacity, color, ductil-ity, and rigidity are all in play, all at once, opening up radical possibilities for embedding structure, energy systems, and visual effects across a continu-ously changing material matrix. The mechanical appearance and behavior of steel, glass, sheet metal, and fasteners is replaced with a new language of blending based won compositing synthetic and biological materials, not in layers, but in new molecular arrangements. The combinatorial range of capacities and aesthetics of polymers, resins, rubbers, silicone, cartilage, and cuticle puts into question the tired frame-and-infill model of design, which is based on extreme disparity of material capacities within hierarchical assemblies. In terms of automobile structural design over the last century, and its oscillations between vector frame and unibody (monocoque) models, the paradigm of multi-materiality offers alternatives away from both mineral logic and machine logic.

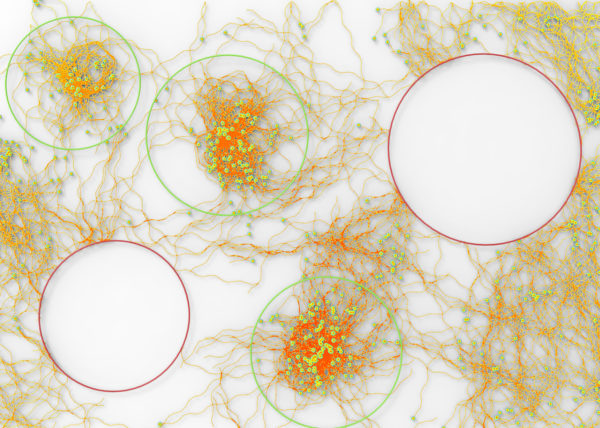

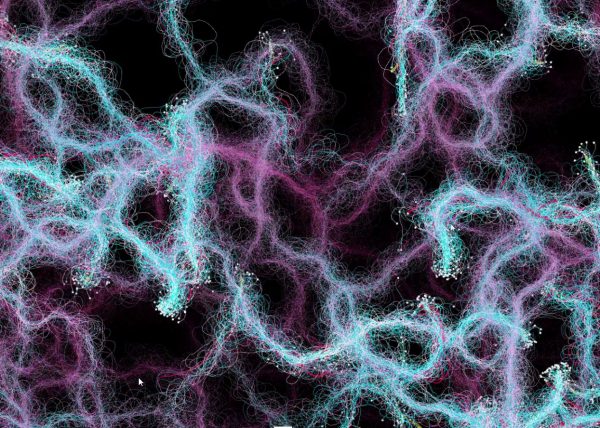

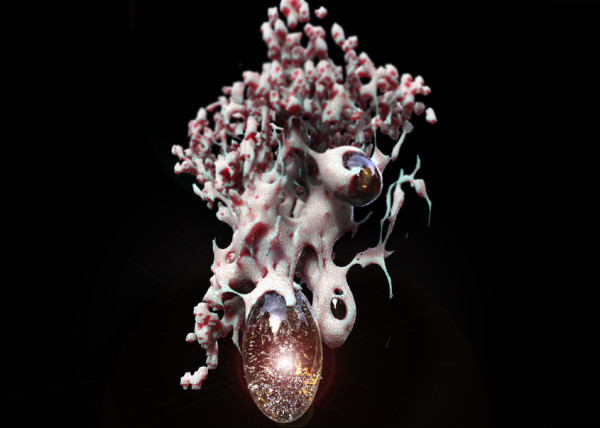

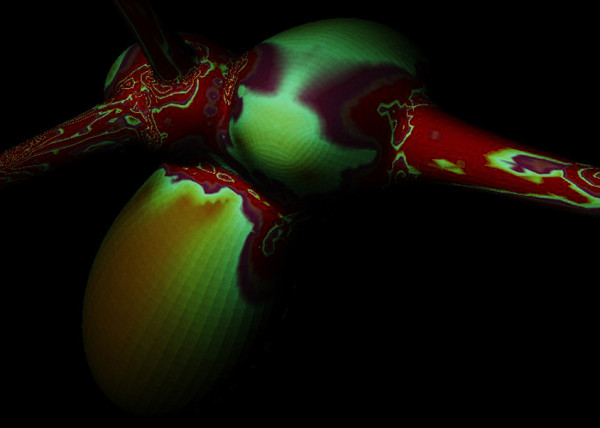

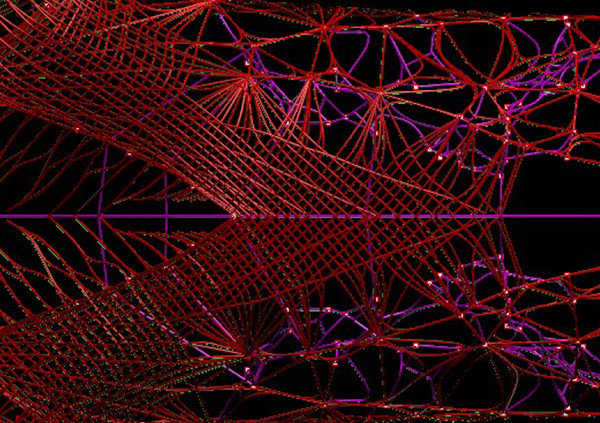

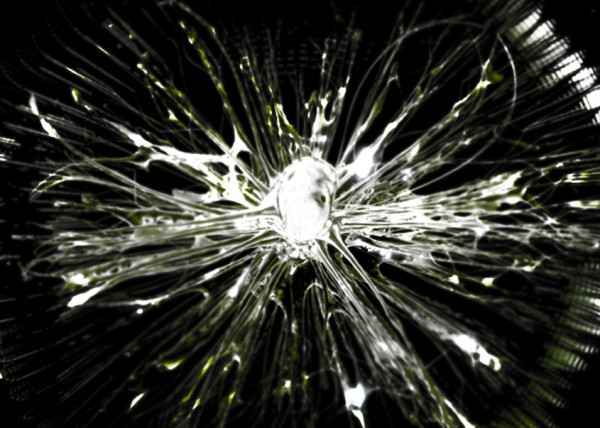

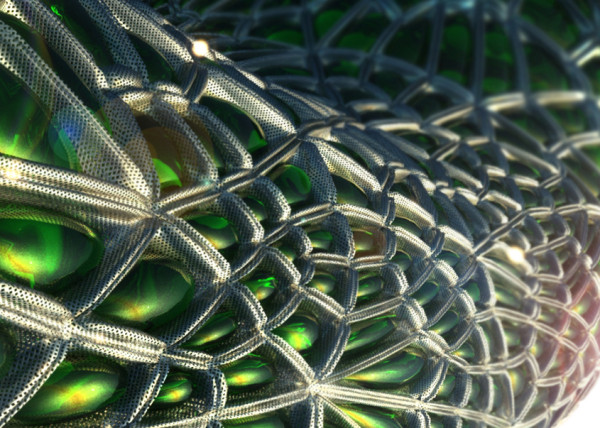

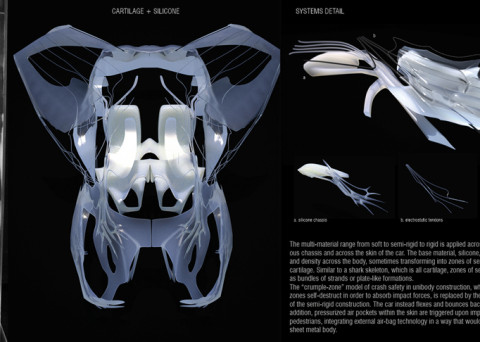

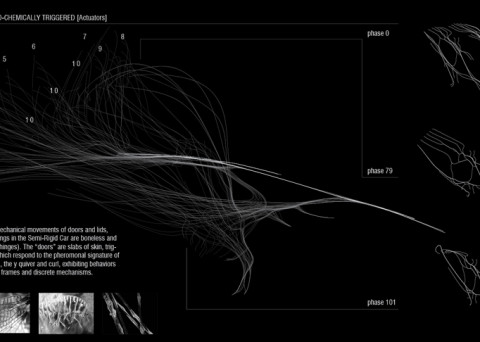

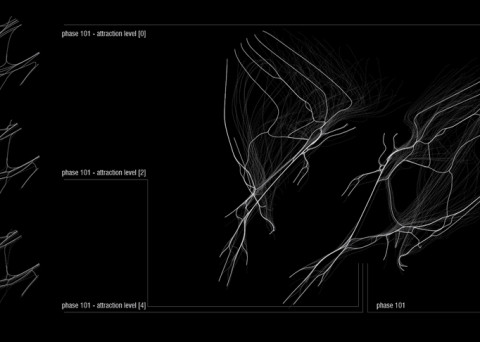

The multi-material range from soft to semi-rigid to rigid is applied across the discontinu-ous chassis and across the skin of the car. The base material, silicone, varies in thickness and density across the body, sometimes transforming into zones of semi-rigid synthetic cartilage. Similar to a shark skeleton, which is all cartilage, zones of semi-rigidity can occur as bundles of strands or plate-like formations. The “crumple-zone” model of crash safety in unibody construction, where front and rear zones self-destruct in order to absorb impact forces, is replaced by the lively springiness of the semi-rigid construction. The car instead flexes and bounces back from impact. In addition, pressurized air pockets within the skin are triggered upon impact with other cars or pedestrians, integrating external air-bag technology in a way that would be impossible in a sheet metal body. Thickness variability of the base material generates variable opacity creating transparent zones for viewing out as well as deep atmospheric views inside the body of the car. The thickest zones are embedded with fluid reservoirs containing algae colonies, forming a photo-bioreactor for the production of bio-fuel. Through the introduction of biolumines-cent bacteria, these reservoirs glow through the silicone at night. The bioreactor distribution network feeds nutrients into each resevoir through thin membranes from the exterior of the soft polymer skin. The skin absorbs nutrients from the outside air.

Text via Tom Wiscombe

Recently in Portfolio

- Nike A.I.R Prototypes

- HE.6 2020 Prototype

- [A]nisochromatic Meshing

- PYTORCH-CLASSIFIER

- CULEBRA.NET

- Nike Zoom Superfly Elite

- Nike Footscape Flyknit DM

- Jordan Hyperdunk React

- KA-HELMET

- PARAPRAXIS

- [001.HRR] CONCEPT BIKE

- [C]ucarachas

- [S]eeker

- BENGBU CITY OPERA

- [O]h Baby

- [E]l Papa

- [S]hatter.Brain

- [S]tigmergy

- [F]orces

- CULEBRA.JAVA

- [C]ulebra.MultiBehaviors

- 2040:LUNAR.OUTPOST[a]

- [S]ticky Stuff

- [S]entinels

- [G]allopingTopiary

- [P]erlin

- [E]ternal Wanderers

- [W]heelie

- [M]esh Crawlers

- [E]l Nino

- [L]a Silla

- [3]D BabyMaking Trackstars

- [3]D Trackers

- [2]D BabyMaking Trackers

- [T]rackers

- CULEBRA GRASSHOPPER

- culebra.[M]eshCrawlers.3D

- culebra.[H]ybrid.3D

- culebra.[F]lorgy

- culebra.[F]ockers.3D

- culebra.[F]ockers.2D

- culebra.[N]oisey.3D

- culebra.[S]elfOrg

- [D]rippin

- [S]labacube

- culebra.[N]oisey.2D

- [C]reepyCrawlers

- [J]eepresesCreepers

- [C]reepers

- [T]2000

- RELUXOED

- [SRC] . Semi Rigid Car

- PUFFER PLEATNESS

- EMERGEN[CY]

- [L]iquified

- [S]uckedComp

- [X]plosion

- MR. EW

- [H]airGoo

- [B]alled

- [n]injaStars

- [b]loomer

- [t]rip city

- TAPE GUNNED

- [B]oom

- [M]iller Time

- [D]elamjam

- [B]rain Zapper

- [B]ig Bird

- IIIIIIII 00137

- [E]gg Tube Pavillion

- [A]llice’s Easter Tree

- [S]weet Honey

- [U]M.Urgent

- [t]oo.urgent

- [B]onnie..+..Clyde

- [B]io Mess

- [EL]Mojado.Virus

- [W]HAT the …!

- [H]ot Lava

- [P]leat Diddy

- [t]erminator easter egg

- Mr. BB

- [B]less You

- [J]acky Jack

- [F]antastic + Interactive

- [S]oo_Minimally_Pathed

- [P]uffer Fish.Fab

- [M]an Eater

- [F]ace Sukka

- [W]eave Machine

- Sportbike Racing

- Grappling

- Kart Racing

Leave a reply