Gallery details

PROJECT DETAILS

project : [001.HRR] Hybrid Race Replica

type : Concept Motorcycle Prototype

date : Private

type : Concept Motorcycle Prototype

date : Private

CMTA Design Directors:

Luis Quinones

Jonathon Stahl

David Stamatis

collaborators:

Juanito Oliviera [Luxigon]

Bob Miller [DesmoValves Racing]

PROJECT DESCRIPTION

DESCRIPTION:

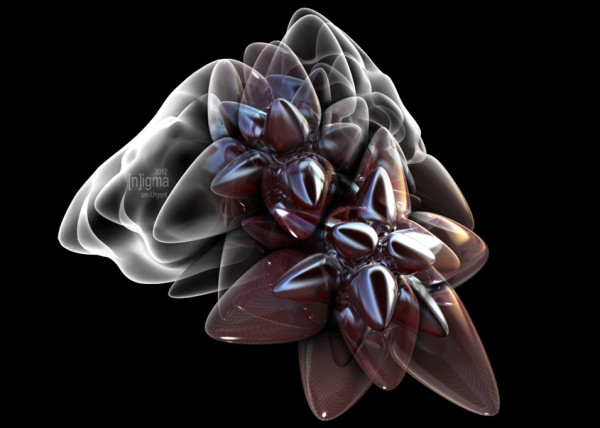

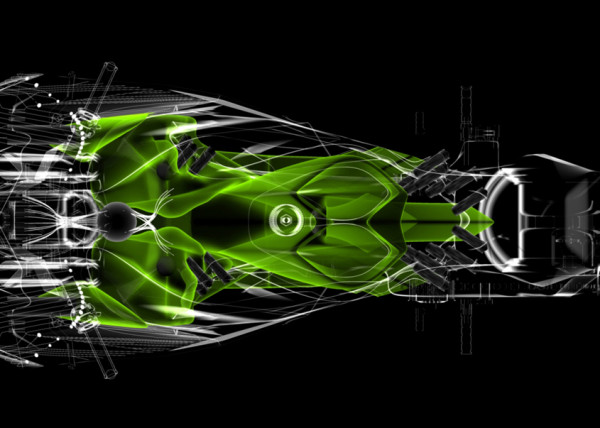

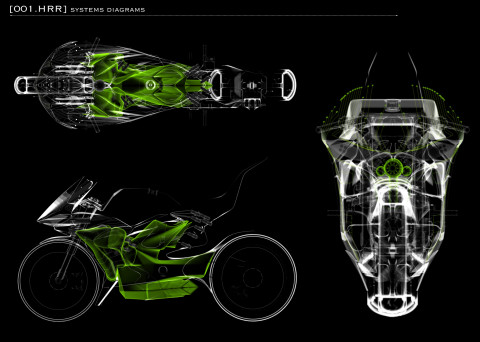

[001.HRR] is a revolutionary concept motorcycle using the cutting edge of material science and technology. A hybrid in some parts, this race replica uses not only thin film solar and paint to harness solar energy but also uses a kinetic energy recovery system [KERS] as a secondary source of power. Our goal was to rethink not only linear manufacturing processes but also evolve a riders experience and safety through the use of technology and materials. The concept from a mechanical/racer perspective was consulted by Bob Miller (DesmoValves Racing) & Luis Quinones (Ducati 848evo WERA Racer). The idea was to maintain a fairly normalized engine package and transmission while innovating in the areas of systems, technology, material research, and manufacturing processes.

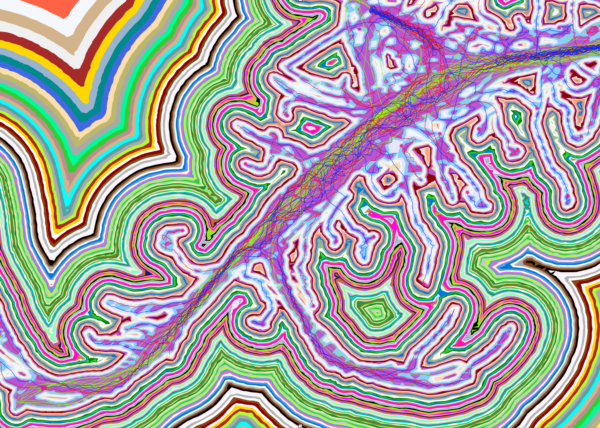

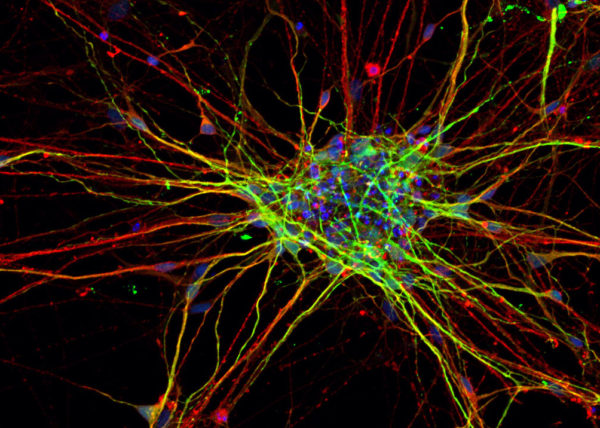

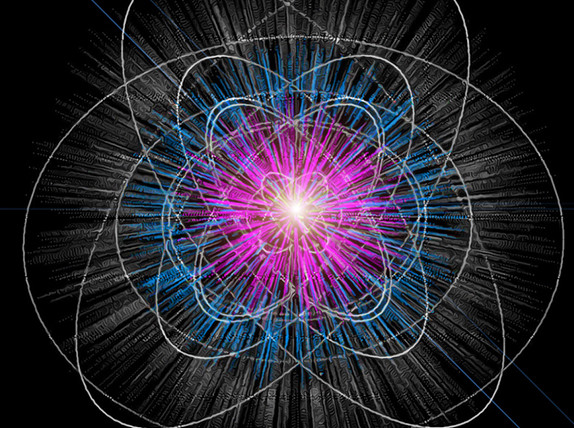

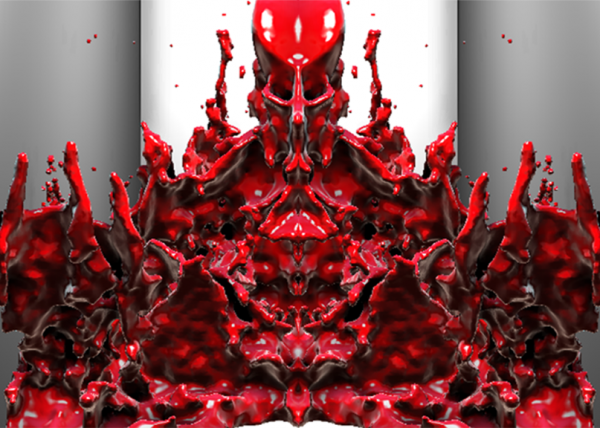

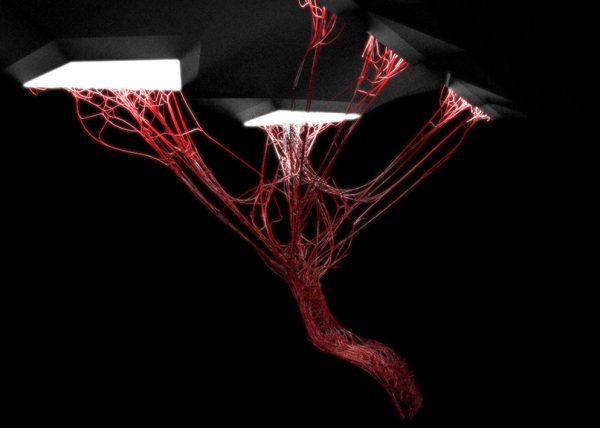

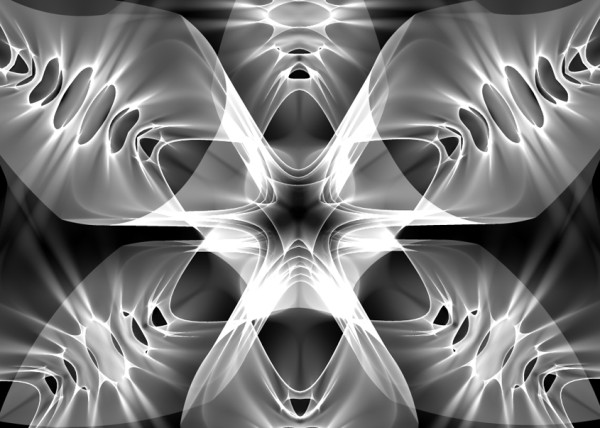

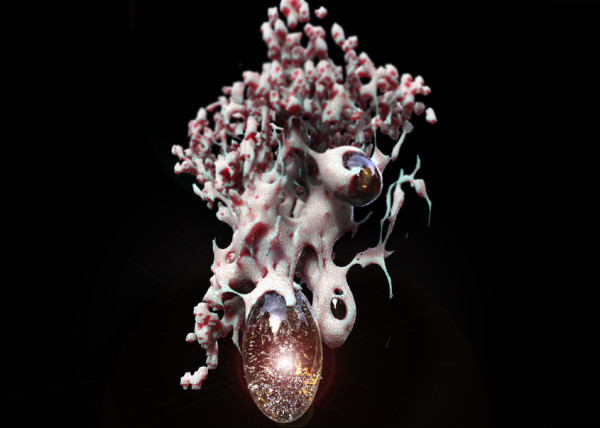

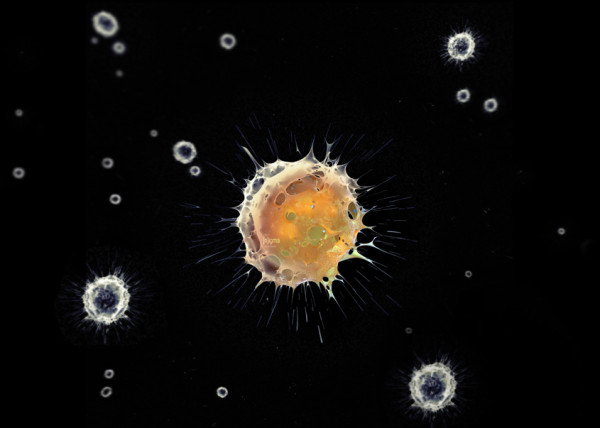

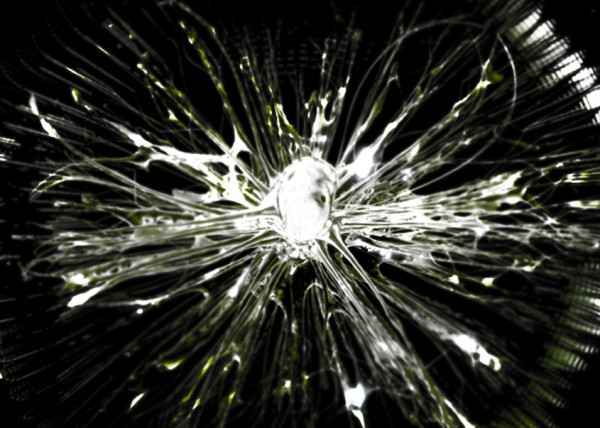

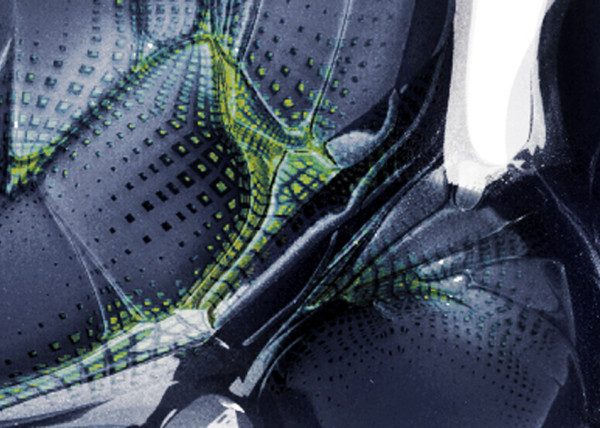

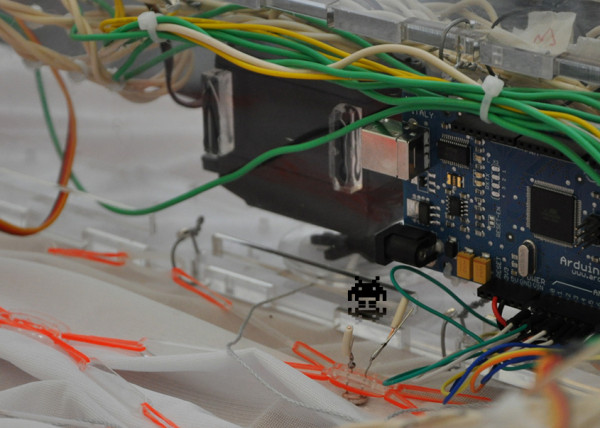

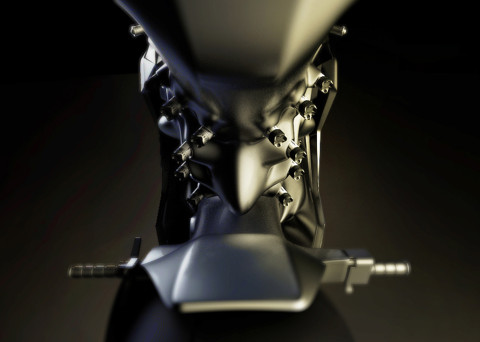

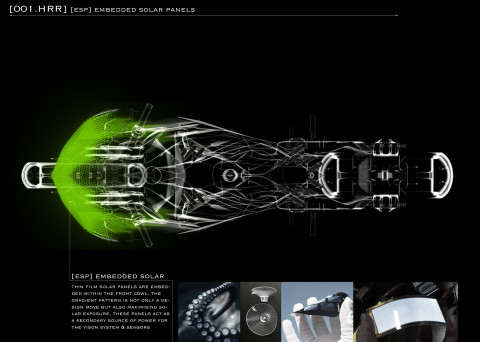

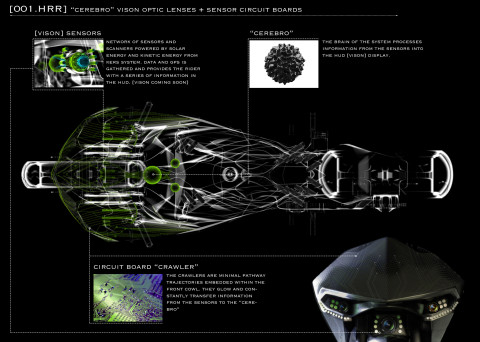

Embedded within the front cowl is a network of custom sensors + “circuit” boards which provide feedback to the helmet HUD [VISON]. The lower front cowl houses the “Cerebro”, a series of high precision optic lenses and sensors which process information for the rider [VISON]. [VISON] allowed us to create a safer motorcycle experience, not only on the street but also on the track. Traditionally “safer” motorcycle concepts involve enclosing the rider inside a shell or protective layer, this is contrary to the spirit of motorcycle riding and racing. Instead [VISON] provides safety in information which is normally not provided as well as eliminating the need to look down at you dash, causing further distractions. This system is powered by a series of “painted” thin film solar sheets embedded in the upper front cowl. These systems along with the emerging circuit board network not only provides power to the sensors but also adds a tectonic quality uncommonly seem in motorcycle fairings.

HRR has 2 modes of operation :

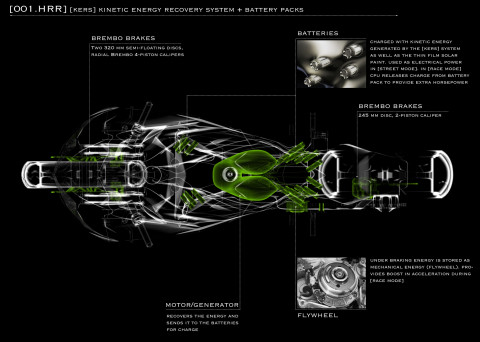

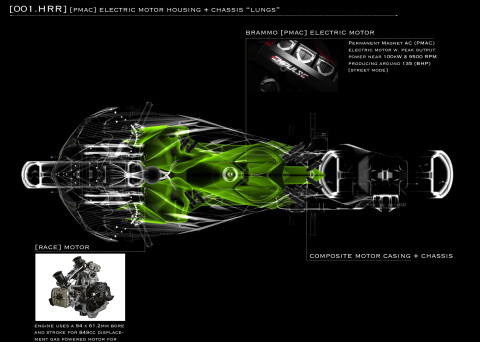

STREET : Consists of a Permanent Magnet AC (PMAC) electric motor w. peak output power near 100kW @ 9500 RPM producing around 135 (BHP). In this mode the KERS system is used to store kinetic energy as electrical power in the rear batteries. Energy from the thin film solar paint is also used to charge the battery pack. Since in street mode the power band is different there is no need for additional power.

RACE : Gas powered mode with full use of the KERS system. In this mode, the energy is stored as mechanical energy (in a flywheel) and provides a boost in acceleration for a limited amount of time. The stored solar energy from the thin film paint is used to power the VISON features for race mode.

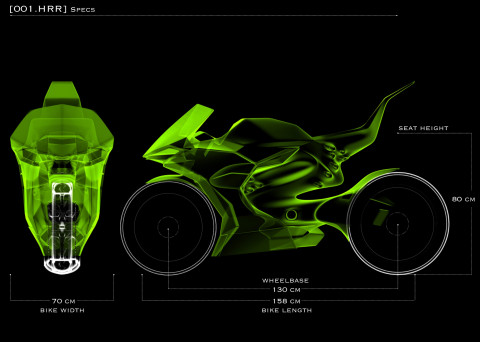

011.HRR SPECS

The HRR concept bike houses Two 320 mm semi-floating discs, radial Brembo 4-piston calipers in the front and a 245 mm disc, 2-piston caliper in the rear, this provides top of the line braking for not only track but also for street use.

Transmission :

6-speed, wet clutch

Suspension :

Front _ Ohlins fully adjustable upside-down forks, 127 mm

Rear _ Ohlins fully adjustable monoshock, 120 mm

Dimensions :

Wheelbase : 130cm

Bike Length : 158cm

Bike Height : 97cm

Seat height : 80cm

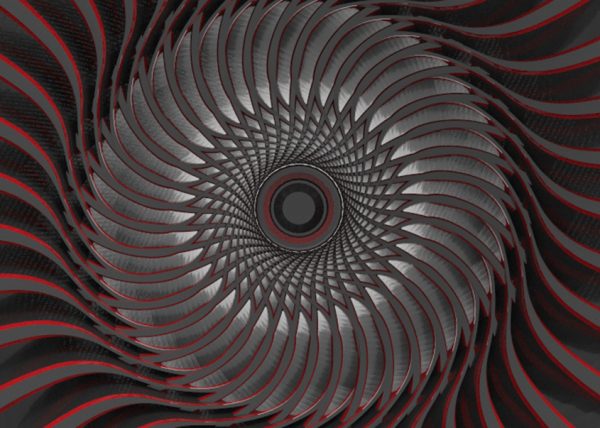

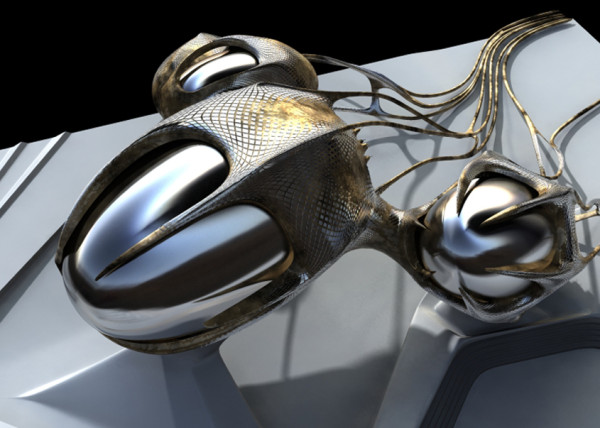

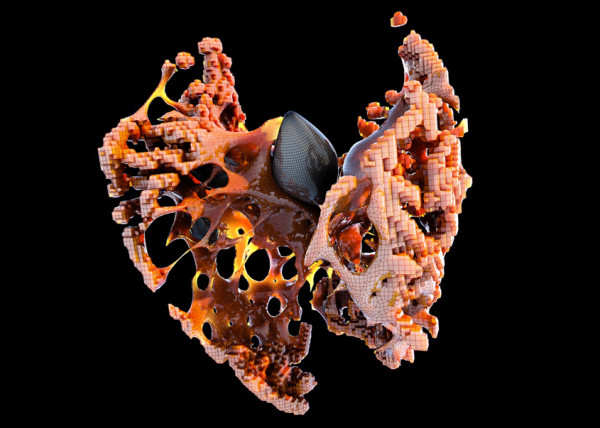

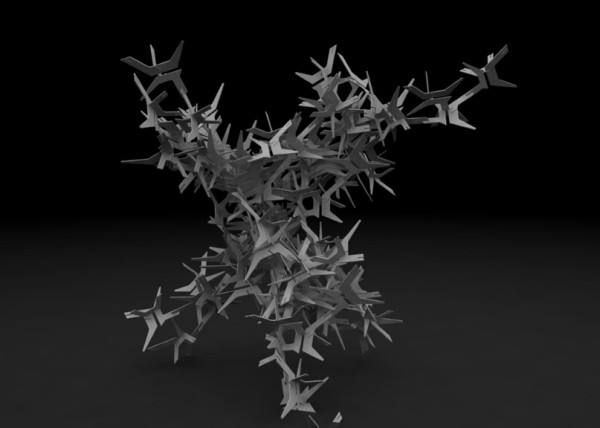

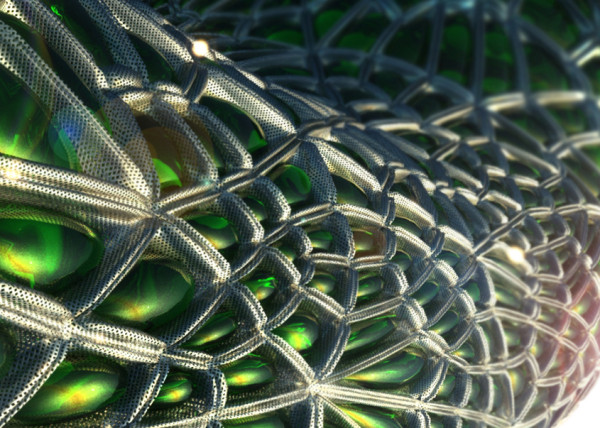

[NLRM] Non-Linear Robotic Manufacturing :

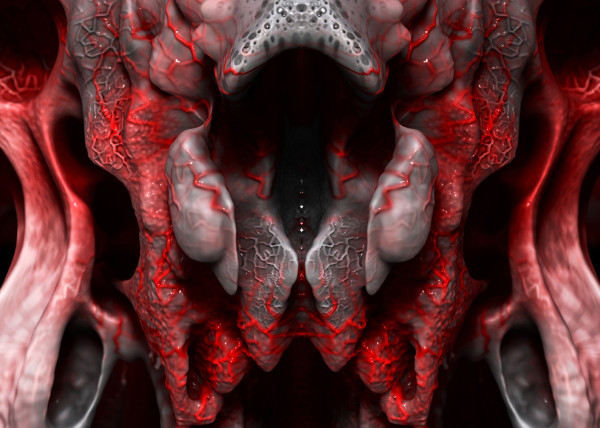

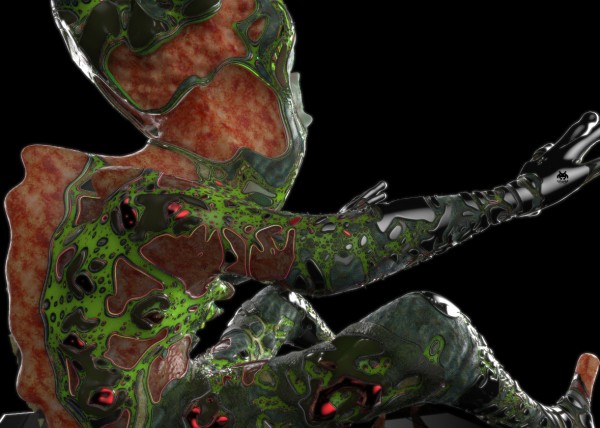

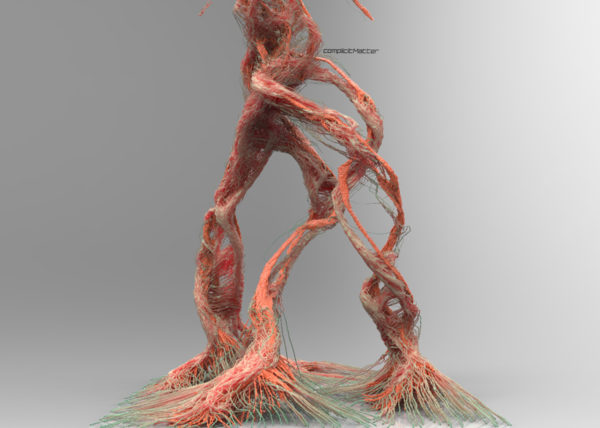

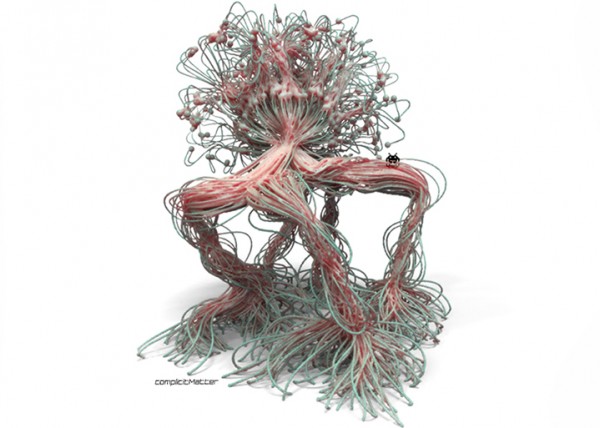

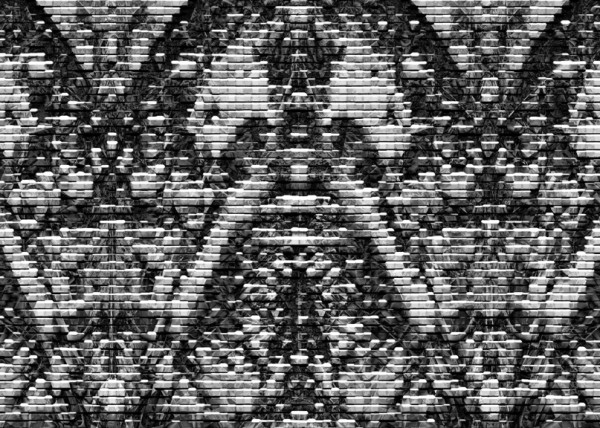

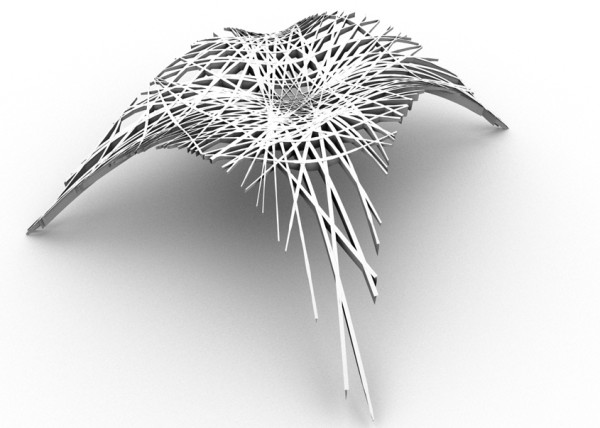

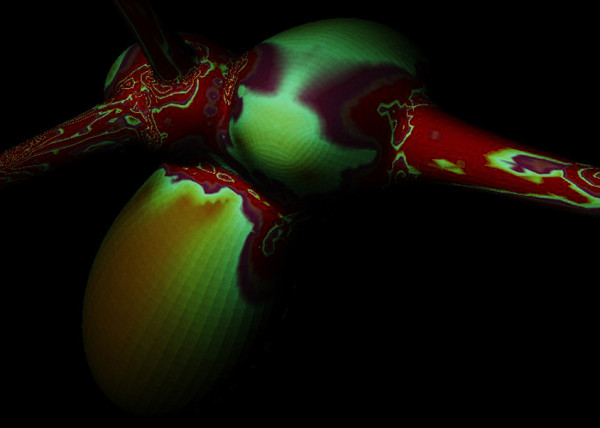

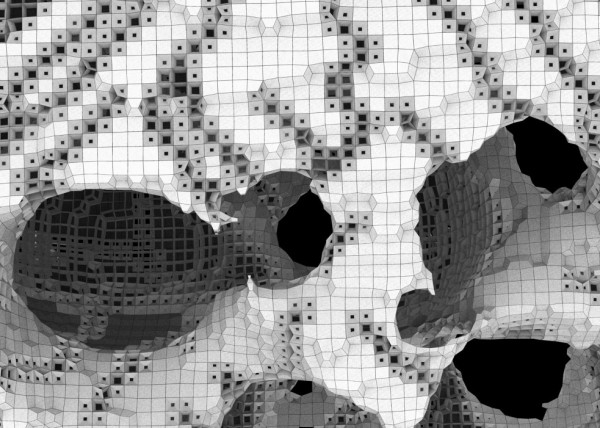

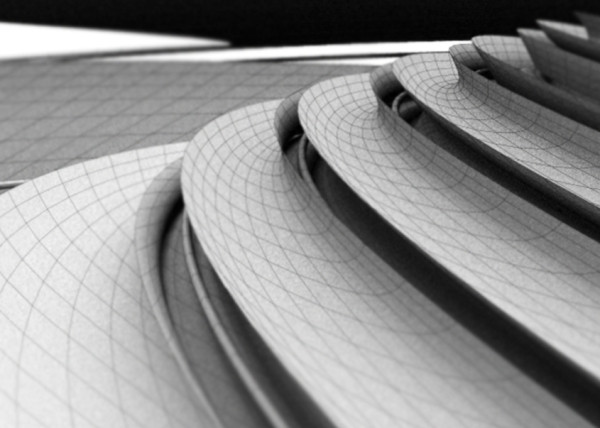

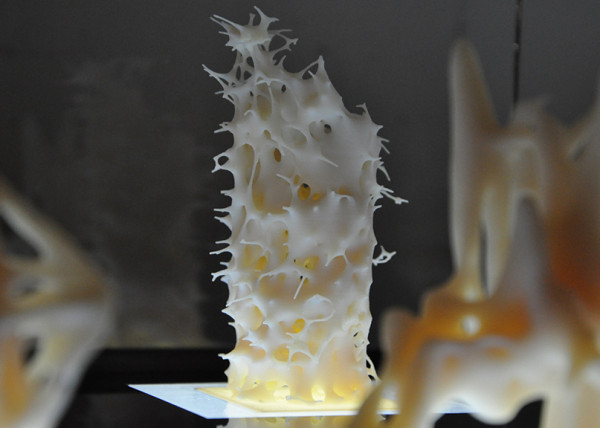

Traditionally fairings are manufactured with ABS molding or a combination of plastic alloy and nylon w. a small percentage of glass fiber. Their sole purpose is aerodynamics and to protect the internal parts. The HRR concept rethinks the function of the fairings and embedded systems in manufacturing.

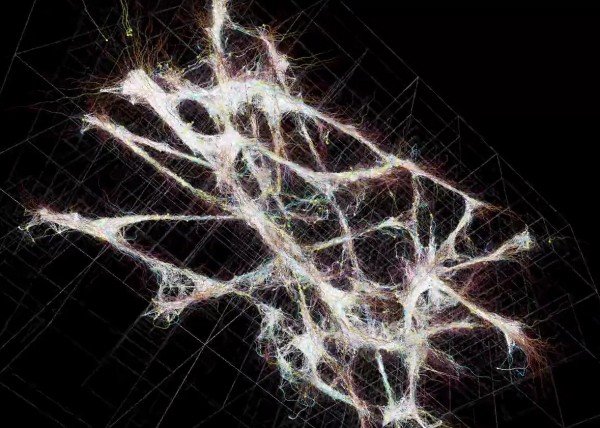

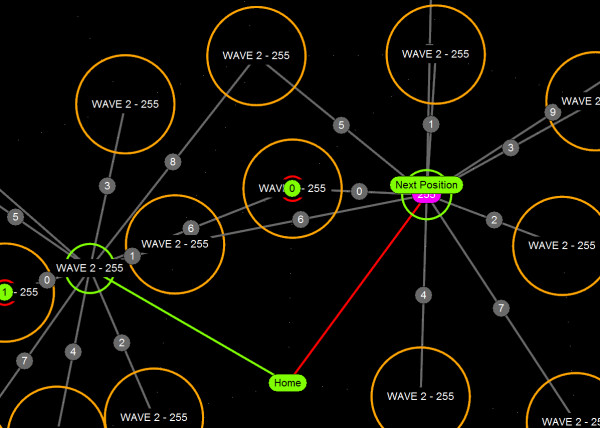

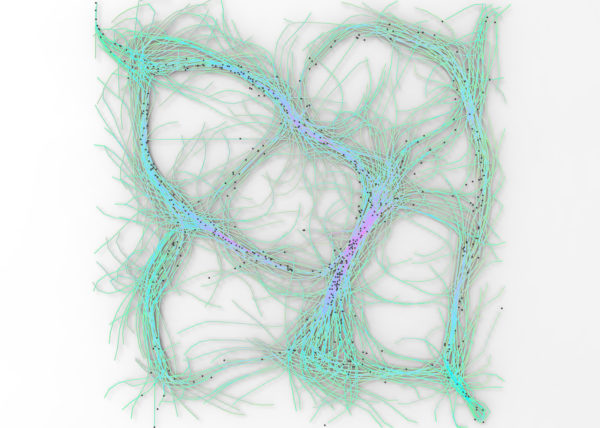

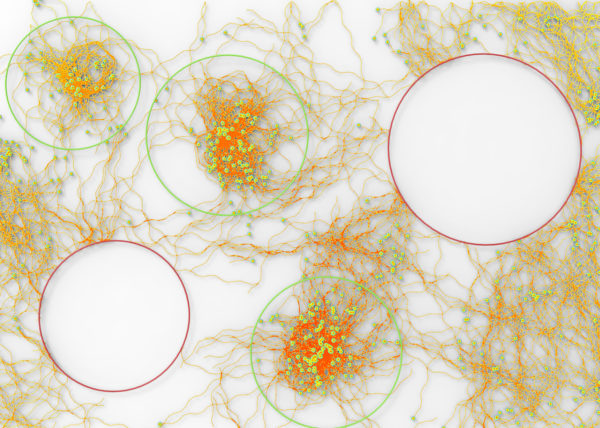

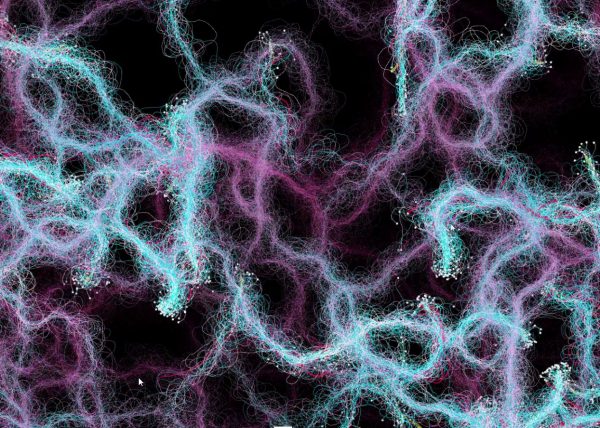

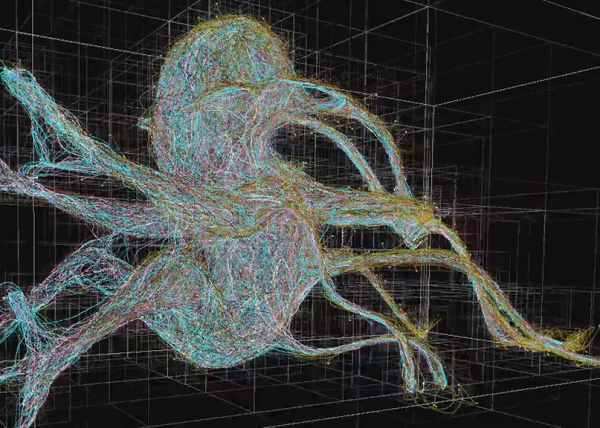

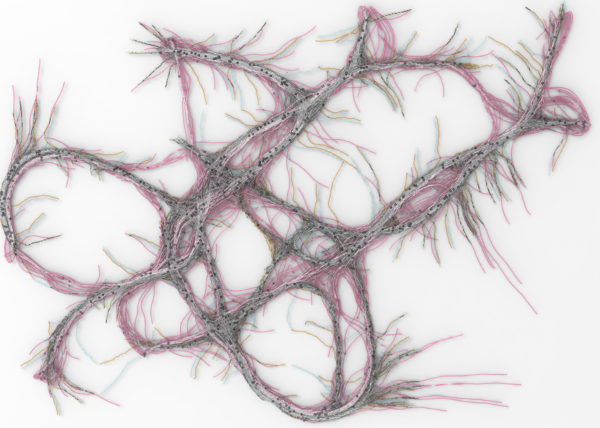

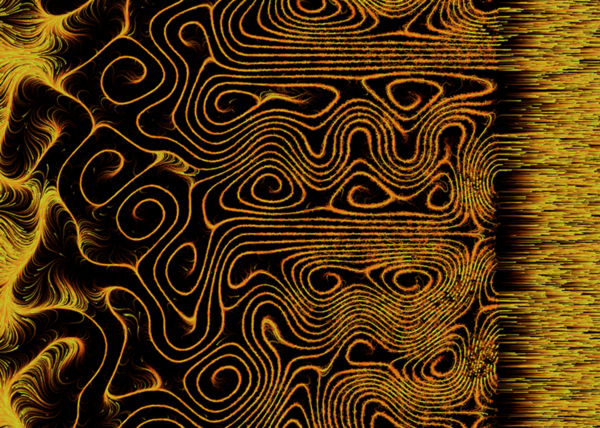

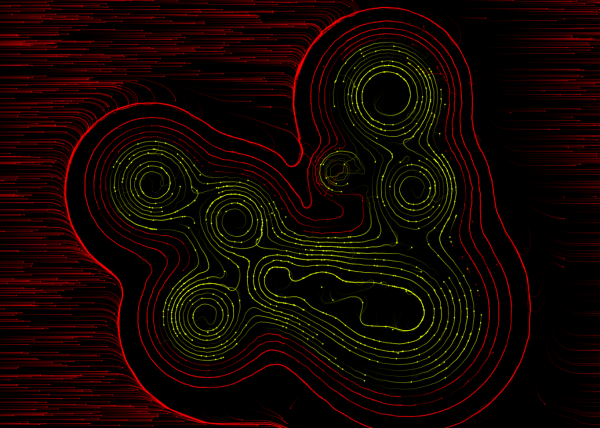

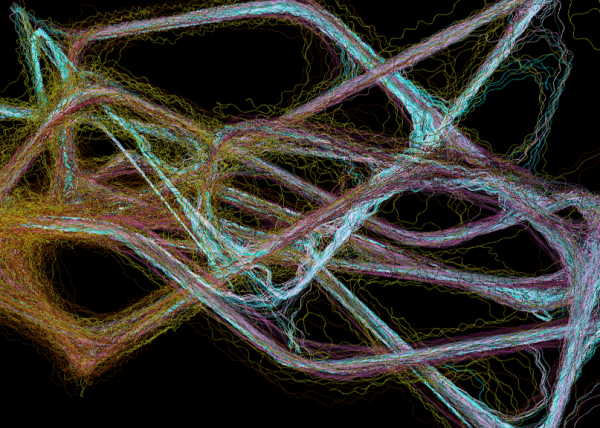

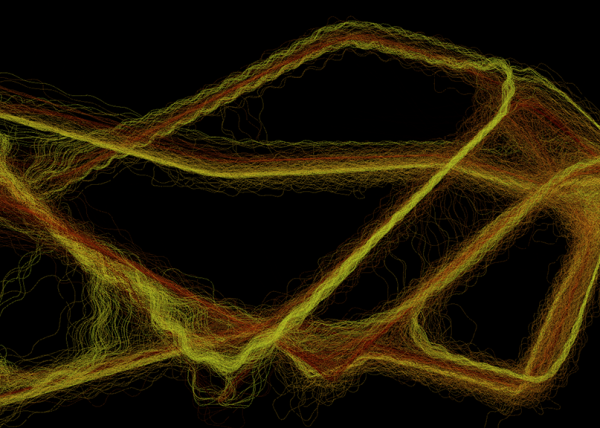

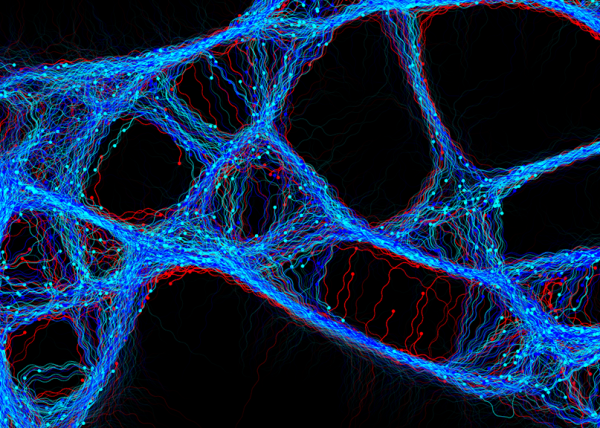

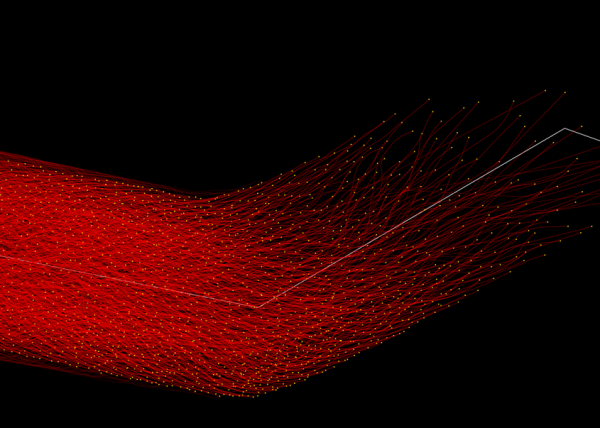

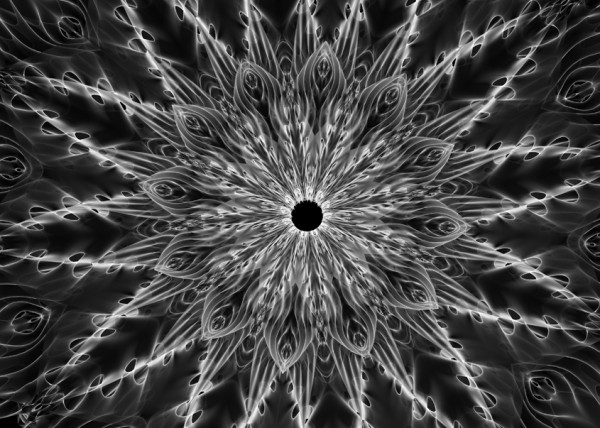

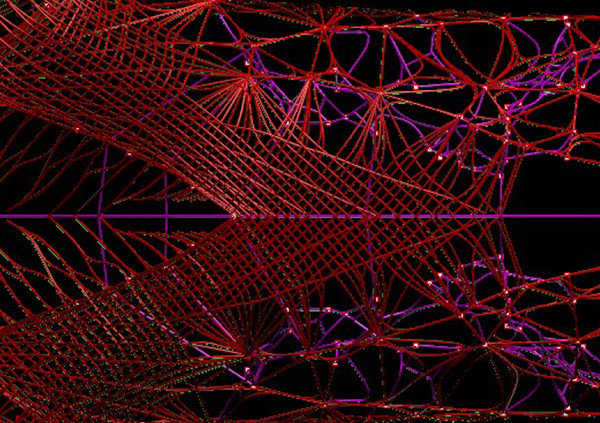

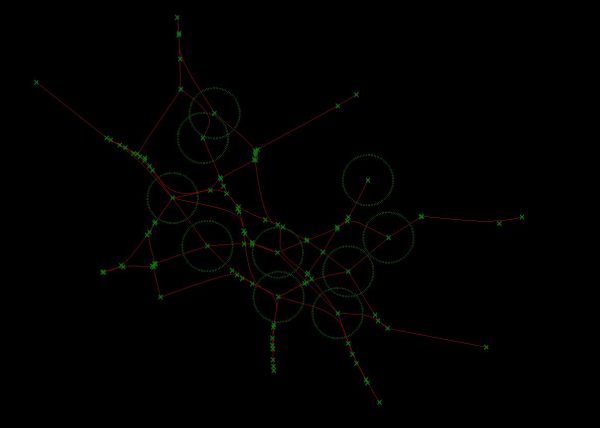

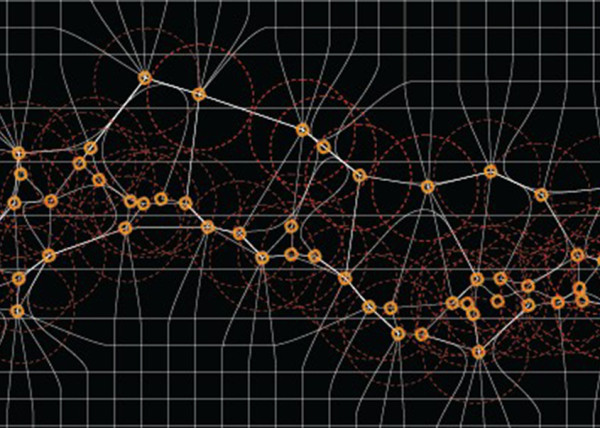

Typically, manufacturing scenarios involve linear procedures, with each robot’s tasks clearly defined. In this project, we seek to explore a non-linear multi-task, multi-stage process of collaborative robotics for the manufacturing of embedded systems into complex 3d surfaces.

The robotic cell will consist of multiple robots with different tools and tasks, in communication. The project explores additive manufacturing using a variety of different fabrication techniques, forming a complex matrix of materials in the form of a fairing. In this heterogeneous method of fabrication, we aim to rethink the idea of tectonics and materials in a generative manufacturing process. In our (non-linear) assembly line, the organization of machines, parts, and assemblies are not uni-directional and cannot be easily described in terms of causality, but rather take on generative potential in a constantly shifting network of manufacturing.

[001.HRR] is a revolutionary concept motorcycle using the cutting edge of material science and technology. A hybrid in some parts, this race replica uses not only thin film solar and paint to harness solar energy but also uses a kinetic energy recovery system [KERS] as a secondary source of power. Our goal was to rethink not only linear manufacturing processes but also evolve a riders experience and safety through the use of technology and materials. The concept from a mechanical/racer perspective was consulted by Bob Miller (DesmoValves Racing) & Luis Quinones (Ducati 848evo WERA Racer). The idea was to maintain a fairly normalized engine package and transmission while innovating in the areas of systems, technology, material research, and manufacturing processes.

Embedded within the front cowl is a network of custom sensors + “circuit” boards which provide feedback to the helmet HUD [VISON]. The lower front cowl houses the “Cerebro”, a series of high precision optic lenses and sensors which process information for the rider [VISON]. [VISON] allowed us to create a safer motorcycle experience, not only on the street but also on the track. Traditionally “safer” motorcycle concepts involve enclosing the rider inside a shell or protective layer, this is contrary to the spirit of motorcycle riding and racing. Instead [VISON] provides safety in information which is normally not provided as well as eliminating the need to look down at you dash, causing further distractions. This system is powered by a series of “painted” thin film solar sheets embedded in the upper front cowl. These systems along with the emerging circuit board network not only provides power to the sensors but also adds a tectonic quality uncommonly seem in motorcycle fairings.

HRR has 2 modes of operation :

STREET : Consists of a Permanent Magnet AC (PMAC) electric motor w. peak output power near 100kW @ 9500 RPM producing around 135 (BHP). In this mode the KERS system is used to store kinetic energy as electrical power in the rear batteries. Energy from the thin film solar paint is also used to charge the battery pack. Since in street mode the power band is different there is no need for additional power.

RACE : Gas powered mode with full use of the KERS system. In this mode, the energy is stored as mechanical energy (in a flywheel) and provides a boost in acceleration for a limited amount of time. The stored solar energy from the thin film paint is used to power the VISON features for race mode.

011.HRR SPECS

The HRR concept bike houses Two 320 mm semi-floating discs, radial Brembo 4-piston calipers in the front and a 245 mm disc, 2-piston caliper in the rear, this provides top of the line braking for not only track but also for street use.

Transmission :

6-speed, wet clutch

Suspension :

Front _ Ohlins fully adjustable upside-down forks, 127 mm

Rear _ Ohlins fully adjustable monoshock, 120 mm

Dimensions :

Wheelbase : 130cm

Bike Length : 158cm

Bike Height : 97cm

Seat height : 80cm

[NLRM] Non-Linear Robotic Manufacturing :

Traditionally fairings are manufactured with ABS molding or a combination of plastic alloy and nylon w. a small percentage of glass fiber. Their sole purpose is aerodynamics and to protect the internal parts. The HRR concept rethinks the function of the fairings and embedded systems in manufacturing.

Typically, manufacturing scenarios involve linear procedures, with each robot’s tasks clearly defined. In this project, we seek to explore a non-linear multi-task, multi-stage process of collaborative robotics for the manufacturing of embedded systems into complex 3d surfaces.

The robotic cell will consist of multiple robots with different tools and tasks, in communication. The project explores additive manufacturing using a variety of different fabrication techniques, forming a complex matrix of materials in the form of a fairing. In this heterogeneous method of fabrication, we aim to rethink the idea of tectonics and materials in a generative manufacturing process. In our (non-linear) assembly line, the organization of machines, parts, and assemblies are not uni-directional and cannot be easily described in terms of causality, but rather take on generative potential in a constantly shifting network of manufacturing.

Recently in Portfolio

- Nike A.I.R Prototypes

- HE.6 2020 Prototype

- [A]nisochromatic Meshing

- PYTORCH-CLASSIFIER

- CULEBRA.NET

- Nike Zoom Superfly Elite

- Nike Footscape Flyknit DM

- Jordan Hyperdunk React

- KA-HELMET

- PARAPRAXIS

- [001.HRR] CONCEPT BIKE

- [C]ucarachas

- [S]eeker

- BENGBU CITY OPERA

- [O]h Baby

- [E]l Papa

- [S]hatter.Brain

- [S]tigmergy

- [F]orces

- CULEBRA.JAVA

- [C]ulebra.MultiBehaviors

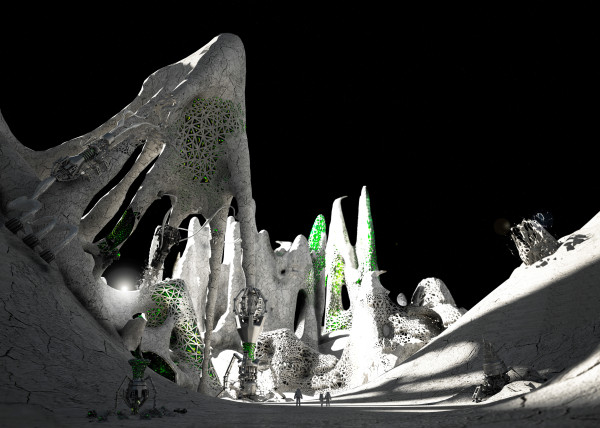

- 2040:LUNAR.OUTPOST[a]

- [S]ticky Stuff

- [S]entinels

- [G]allopingTopiary

- [P]erlin

- [E]ternal Wanderers

- [W]heelie

- [M]esh Crawlers

- [E]l Nino

- [L]a Silla

- [3]D BabyMaking Trackstars

- [3]D Trackers

- [2]D BabyMaking Trackers

- [T]rackers

- CULEBRA GRASSHOPPER

- culebra.[M]eshCrawlers.3D

- culebra.[H]ybrid.3D

- culebra.[F]lorgy

- culebra.[F]ockers.3D

- culebra.[F]ockers.2D

- culebra.[N]oisey.3D

- culebra.[S]elfOrg

- [D]rippin

- [S]labacube

- culebra.[N]oisey.2D

- [C]reepyCrawlers

- [J]eepresesCreepers

- [C]reepers

- [T]2000

- RELUXOED

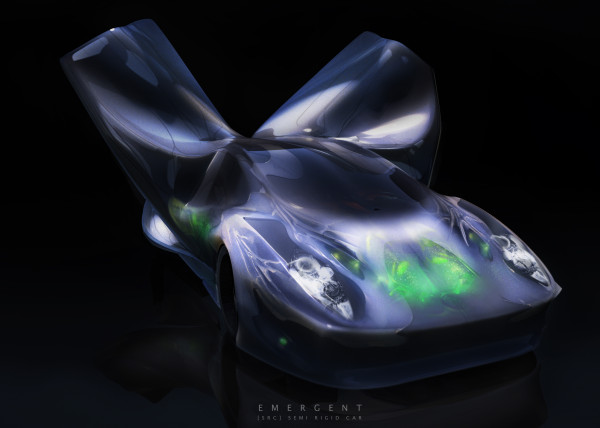

- [SRC] . Semi Rigid Car

- PUFFER PLEATNESS

- EMERGEN[CY]

- [L]iquified

- [S]uckedComp

- [X]plosion

- MR. EW

- [H]airGoo

- [B]alled

- [n]injaStars

- [b]loomer

- [t]rip city

- TAPE GUNNED

- [B]oom

- [M]iller Time

- [D]elamjam

- [B]rain Zapper

- [B]ig Bird

- IIIIIIII 00137

- [E]gg Tube Pavillion

- [A]llice’s Easter Tree

- [S]weet Honey

- [U]M.Urgent

- [t]oo.urgent

- [B]onnie..+..Clyde

- [B]io Mess

- [EL]Mojado.Virus

- [W]HAT the …!

- [H]ot Lava

- [P]leat Diddy

- [t]erminator easter egg

- Mr. BB

- [B]less You

- [J]acky Jack

- [F]antastic + Interactive

- [S]oo_Minimally_Pathed

- [P]uffer Fish.Fab

- [M]an Eater

- [F]ace Sukka

- [W]eave Machine

- Sportbike Racing

- Grappling

- Kart Racing

Leave a reply